Menlo Logistics Tallies Progressive Growth in Southeast Asia and Singapore

Singapore Site Visits

May 29, 2014

By

Evan Armstrong

Key Personnel:

Robert Bassett, Senior Vice President of Sales & Marketing

Desmond Chan, Managing Director – Southeast Asia

Thomas Koh, Director of Operations

Desmond Lim, Deputy General Manager

Cheston Ang, Operations Manager

Agnes Tan, Assistant Operations Manager

Menlo Logistics Overview

In 2013, Menlo Logistics generated gross revenue of $1.5 billion and its net revenue grew to $681 million. Menlo’s global staff of approximately 9,000 manages operations in 20 countries on five continents. Its warehousing footprint includes 138 facilities with over 20 million square feet of space. Menlo was an early adaptor of “Lean” Management principles and has engineered tier-one inbound supply chain management and finished goods distribution capabilities. Its IT capabilities and ample engineering resources provide Menlo with solid supply chain management and optimization capabilities.

Menlo Logistics Southeast Asia

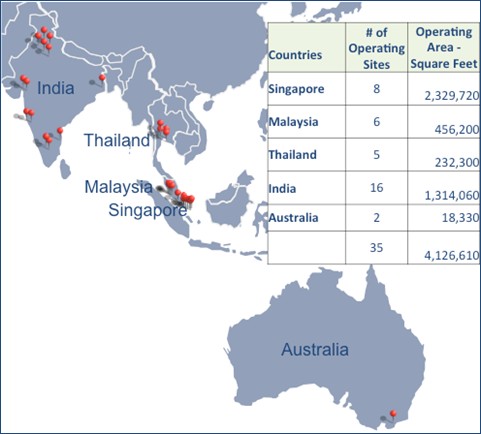

Menlo’s Southeast Asia operations boast a staff of over 1,800 serving 228 customers. Its Southeast Asia operations are headquartered in Singapore where it supports local domestic logistics operations and operations in Malaysia, Thailand, India, and Australia. Over the past two years, further business growth has driven Menlo to expand its Southeast Asia operating network by one million square feet, making its overall footprint 4.1 million square feet.

Menlo’s Southeast Asia Operating Network

Singapore has been a noteworthy growth market for Menlo. We estimate it is one of the top 10 Value-Added Warehousing & Distribution 3PLs in Singapore with 2.3 million square feet of warehousing space. India has also been growing rapidly with Menlo currently managing 16 operating locations compared to four locations in 2009.

Menlo’s Southeast Asia supply chain management service offering mirrors that of its U.S. operations and includes fourth- and third-party logistics management services (4PL/3PL), value-added warehousing and distribution, and domestic transportation management. Approximately 80% of its Southeast Asia revenues are from customers marketing consumer goods.

While in Singapore, we had a chance to review two of Menlo’s newest warehouses: Sunview which was opened in 2013 and Benoi which Menlo began occupying in January 2014. As a note, both operations have been assessed as being environmentally sustainable via its BCA Green Mark GoldPlus Certification.

Sunview Multi-client Regional and Domestic Value-Added Warehousing & Distribution Operation

Menlo manages 400,000 square feet encompassing four floors of the bonded multi-client Sunview warehouse. The operation has a total staff of 72 processing over 11,000 orders per month from over 9,500 stock keeping units of on-hand inventory for its customers. Along with being a bonded free trade zone (FTZ) facility, Sunview is also a Zero-GST facility where customers can warehouse goods on a GST (Goods and Services Tax) free basis. The value-added GST tax is only paid once the goods are purchased in Singapore and exported goods do not incur Singapore’s GST. Each floor has 11 dock doors. Floors 1-7 have 10-meter high ceilings and level 8 has 12-meter high ceilings.

Menlo’s 100,000 square foot dedicated customer operation is managed by a full-time warehouse staff of 34 on the seventh floor of the Sunview warehouse. Through ongoing process improvement efforts, the operation has obtained Menlo’s Bronze Lean Certification. Products including printers,

cameras, camera lenses, and projectors are maintained in on-hand inventory for domestic Singapore distribution and regional distribution to Southeast Asian countries including: Malaysia, Nepal, Thailand, and Vietnam. Most export products are shipped in LCL (less than container load) and FCL (full container load) ocean freight quantities.

Menlo uses its Provia WMS (warehouse management system) to drive warehouse operations. The WMS is integrated with the customer’s ERP (enterprise resource planning) system for order management and visibility. Product is received from Vietnam via ocean containers where it was loaded onto slip sheets. During receipt, each item’s serial number is captured using RF (radio frequency) devices prior to putaway.

The majority of items are maintained in two types of racking: goods for export are stored in drive-in racking, which is conducive for ocean container shipping volumes and products for domestic Singapore distribution are maintained in four- to six-high conventional racking. Items for regional distribution are picked in pallet quantities. For Singapore, there is some carton and individual piece picking. In addition to the ambient warehousing space, there is also a 3,000 square foot caged area for cameras and a 2,800 square foot 20 degree Celsius air conditioned/humidity controlled room for special lenses and projectors. Security is important. In addition to secured entry points, Menlo uses 34 CCTV (closed circuit television) cameras to monitor the operation.

On the third floor of Sunview, Menlo operates a dedicated 100,000 square foot value-added warehousing and distribution operation. This operation has also obtained Menlo’s Bronze Lean Certification. With a full-time staff of 28, the operation fulfills orders from storage locations in five-high racking and bulk storage.

Menlo utilizes its proprietary “SIMS” WMS to manage the operation. Orders vary between pallet pick, case pick, to each pick. The majority of outbound orders are destined to Singapore, Indonesia, Malaysia, Thailand, the Philippines, and Vietnam.

The operation performs a host of value-added services including price tagging, local market labeling, DVD coding, packaging, and returns processing. In a small, separate room of the third-floor operation, Menlo is running a baby bottle packing operation. Between 4,000-5,

Two operations are managed for a customer in 32,000 square feet of the facility’s first floor. Half of the operation is dedicated to automotive parts distribution and a power tool warehousing and distribution operation is housed in the other half. This operation has obtained Menlo’s Silver Lean Certification.

Daily outbound parts and power tool orders are processed by a staff of 10. Automotive parts are maintained in 1,900 pallet positions in six-high racking, in 6,000 bin/shelve locations, and in bulk storage. Approximately 60% of the outbound automotive parts orders are for the local Singapore market and the rest are exported to the neighboring countries of Indonesia, Malaysia, Thailand, the Philippines, and Vietnam. The power tools stored in the warehouse are distributed solely within the local Singapore market. Menlo manages two dedicated local delivery trucks as part of the operation.

In addition to inventory management, order fulfilment, outbound distribution, and postponement, Menlo is also performing local market product labeling as a value-added service.

The remaining 68,000 square feet of the first floor is utilized for multiple smaller, public warehousing customers and is primarily pallet in/out business.

At the time of our visit, Menlo was exceeding all KPI (key performance indicator) performance targets for these three customers. Major KPIs being measured include damages, inbound/outbound lead times, on-time delivery, order fulfilment (stock-to-dock), inventory accuracy, order accuracy, and receiving to stock.

Benoi Multi-client Value-Added Warehousing & Distribution Operation

With its grand opening in March 2014, Benoi marks Menlo’s latest warehouse addition in Singapore. The operation focuses on meeting the domestic distribution needs of Menlo’s growing list of Wine and Spirits customers. At the time of our visit, Menlo was moving the majority of its Wine and Spirits operations “up” from its Boon Lay warehouse to the Benoi warehouse where it occupies floors 3 to 5 each having 194,000 square feet for a total of 582,000 square feet.

On level 3 of the warehouse, Menlo’s warehouse staff of 17 manages operations for three customers. Level 3 has 21 dock bays and ceiling heights up to eight meters.

Its new Benoi value-added warehousing and distribution operation occupies 18,959 square feet of non-bonded warehouse space and fulfills orders to approximately 60 retail stores for shoes, apparel, golf clubs, and accessories for one of the few non-Wine and Spirits customers at Benoi. Approximately 70% of outbound orders are for retailers in Singapore and the remaining 30% are exported to other Southeast Asia countries including Brunei, Malaysia, Thailand, and Vietnam. Products are stored in conventional racking and Menlo is using its proprietary SIMS WMS connected to RF devices to manage the operation.

Value-added services performed include inbound product receiving and quality/quantity inspections, premium product handling, price tagging for domestic orders, and returns management. Menlo also supports this customers ad-hoc promotional events such as tradeshows and campaigns.

Menlo is exceeding its KPI performance benchmarks, which include: Web visibility to reflect real-time data of inbound/outbound orders and stock availability, on-time receiving performance, order fulfillment, delivery and reporting performance, inventory accuracy, and data accuracy for system updates.

A Wine and Spirits customer’s operation has 32,586 square feet of bonded spirits inventory. All of its products are for export to North Asian countries including China, Hong Kong, and Japan. Inbound containers of product are received and checked against orders to verify quantities. Next, they are putaway into the respective storage areas based on their storage requirements. Each case and bottle is tracked while in inventory.

Palletized cases of spirits are stored in 6’ x 4’ drive in racking in about 12,000 square feet of the operation. The drive in racking allows FCLs to be efficiently putaway and picked as orders come in. Menlo is applying price tags and import labels to bottles as a value-added service.

This Wine and Spirits customer’s other operation has 62,676 square feet of bonded spirits inventory. About 80% of its products are for export to Southeast Asia countries and the remainder is stored in an import duty paid area for local Singapore distribution. Palletized cases of spirits for export are stored in 6′ x 4′ drive in racking. This allows FCLs to be efficiently putaway and picked. Menlo is applying bottle cap security labels to exported spirits as a value-added service.

Menlo is using its proprietary SIMS WMS connected to RF devices to manage both of this Wine and Spirits customer’s operations.

On level 4 of the warehouse, Menlo’s warehouse staff of 20 manages bonded warehousing operations for two other Wine and Spirits customers. One operation is 36,395 square feet and the other is 56,454 square feet. There is also a 23,000 square foot temperature controlled section being utilized by multiple Wine and Spirits customers for wine and champagne. Warehouse levels 4 and 5 have 26 dock bays on each floor. As in the previous operations, items were being exported to Southeast Asia and domestically in Singapore. Menlo is using its SIMS WMS and is also performing product labeling as a value-added service.

Level 5 of the Benoi warehouse was being built out for final occupancy at the time of our visit.

Summary

Menlo has seen strong business growth in Southeast Asia with its Lean management approach and modern value-added warehousing and distribution operations. Its model is playing well with companies with consumer goods for distribution within Southeast Asia, North Asia, and within local domestic markets.

Sources: A&A Primary Research, https://www.xpo.com