Penske Logistics Leverages Multinational Relationships in Expanding Asian Operations

Shanghai, China

October 2007

By

Evan Armstrong

Key Personnel:

Jim Erdman, Senior Vice President – Asian Operations

Joseph Gallick, Senior Vice President of Sales

Aditya Mishra, CFO – Asian Operations

Gary Franz, Vice President of Sales – Global Accounts

Victor Wang, Logistics Manager

Peter Wei, Operation Manager – Warehouse Management

Scott Zhang, Continental Project Manager – Logistics Engineer

The third-party logistics (3PL) industry in China is a tale of two major 3PL market segments–international freight forwarding and domestic warehousing and distribution. Over the last 15 years most 3PL revenue growth has been generated by international air and ocean freight forwarding. The domestic market includes 3PLs such as Penske Logistics whose main focus is on supporting the distribution of goods within the domestic Chinese market. As the Chinese per capita income increases, its population of 1.4 billion will continue to demand more and more goods. To support this demand significant improvements are beginning to be made in domestic warehousing and distribution. Due to the developing Chinese economy and increased personal wealth, it is easy to argue that freight forwarding will grow at some factor of China’s GDP, while the domestic 3PL market holds greater long-term potential.

To position itself to meet the long-term potential of the domestic Chinese 3PL market, in 2005 Penske Logistics established its Asian headquarters in Shanghai, China. Initially Penske Logistics began operations as a consulting licensed Wholly Owned Foreign Entity (WOFE). Then in 2006 it made an acquisition of a local logistics provider. Through the acquisition, Penske Logistics became a licensed international trading company, Class A licensed freight forwarder, and customs broker. Today Penske Logistics has a staff of over 100 in China, manages five facilities totaling 140,000 square feet, and generates revenues of $5M.

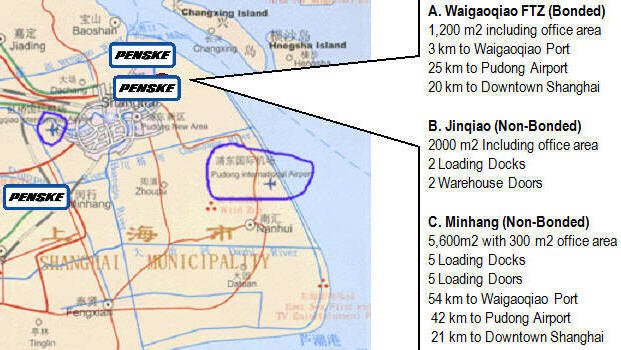

Penske Logistics Shanghai, China Operations

Penske Logistics current projects in China include: warehousing and distribution management for Continental Tire, export consolidation and international transportation management for Knoll, international transportation management for Key Safety Systems, managing an international J.I.T. hub for Eaton, customs clearance and domestic distribution for GE, and import and domestic distribution management for BMW. In addition, it has begun operations in a new 5,000 m2 material supply center (pictured below) for BMW Brilliance Automotive in Shenyang and a 500 m2 warehouse in Beijing for BMW AG (marketing products).

Continental Tire Domestic China Warehousing and Distribution Management

Penske Logistics custom designed a 60,277 square foot non-bonded distribution center for Continental Tire in the Minhang district of southwest Shanghai and has occupied the new facility since September of 2007.

As part of its warehouse management functions, Penske Logistics engineered the optimal warehouse layout and stock placement strategy for an average inventory of approximately 55,000 passenger vehicle tires representing over 100 stock keeping units (SKUs). Penske Logistics staff of 15 utilizes Continental’s SAP information system for inventory management, warehouse order picking and putaway.

It also performs inbound and outbound transportation planning and order fulfillment of approximately 8,000 to 10,000 tires per week destined to Continental’s Chinese dealer network.

Waigaoqiao Multi-Client Logistics Center

A short drive from downtown Shanghai is the Waigaoqiao free trade zone (FTZ) and ocean shipping port. Penske Logistics runs a 12,960 square foot bonded logistics center managing customers’ import/export, customs brokerage, and short-term storage activities. Customers such as Sandvik and Amcor are supported by a staff of 12.

Most products handled at the center are imported goods being distributed within China. Penske Logistics has permission to use the Chinese government’s customs information system to track inbound product through customs clearance. Its staff notifies customers of product movement and final clearance. In addition, they prepare the necessary documentation for domestic distribution. It takes approximately 24 hours to clear Waigaoqiao customs.

To support its logistics center operations, Penske Logistics utilizes the popular Chinese warehouse management system (WMS) “Flux WMS”. Flux provides good warehouse management and inventory control functionality, can support radio frequency devices for picking and putaway, and can be integrated with most major enterprise resource planning systems such as SAP. Penske Logistics is currently running an RFID active pallet tag test using Flux for GE.

Summary

Penske Logistics is leveraging its multinational customer base and expanding local expertise to grow its operations in China. It has successfully positioned the company as both a “China Gateway” for U.S. and European customers moving material and product in and out of China and as an established domestic China 3PL managing internal transportation, providing warehousing and distribution, and supporting plants with its tier-one inbound logistics services. Paired with the alliance air and sea transportation services Penske offers with ABX Logistics, customers can benefit from a full range of 3PL value-added services. In the near future, as it links China with other regions through its global transportation management platform, true event management via a single portal or system will be possible. As the domestic Chinese contract logistics market develops, we anticipate that Penske Logistics will have a solid network in place to address the needs of both multinational customers and domestic Chinese shippers.

Sources: A&A Primary Research, http://www.penskelogistics.com/