Infor Nexus and Integrated Warehouse Management Systems Enhance Collaboration and Supply Chain Management

New York, New York USA Site Visit

November 15, 2021

By

Evan Armstrong

&

Cheri Grabowski

Key Personnel:

Heidi Benko, Vice President Solutions Strategy & Marketing

Vishal Minocha, Vice President, Product Management and GTM

John Nadvornik, Vice President Product Management

Helenara Prati, Director Americas and EMEA Ocean Services

Dave Morgan, Senior Solutions Consultant

Timothy Shea, Senior Account Executive

Infor Overview

In 2002, Infor was founded as Agilisys, an enterprise software company. After nearly two decades of strategically acquiring software companies such as Lawson Software and GT Nexus, Infor works with 65,000 customers in 177 countries. Infor’s Third-Party Logistics (3PL) centric solutions set includes P.O. Management, Origin Consolidation Management, Transportation Sourcing, and Control Center functionality within the Infor Nexus application which is integrated with Infor WMS for warehouse management.

Infor has long standing relationships with 3PL customers including DHL, Kuehne + Nagel, UPS, and CEVA Logistics, as well as mid-market players such as Allport Cargo Services and Future Supply Chain Solutions, which are detailed below.

Infor Nexus Platform

The Infor Nexus platform connects global supply chain partners to manage orders and shipments from origin to destination. Carrier tracking interfaces provide live updates on the delivery status and location of shipments. Users can easily view late, early, and on-time status updates allowing for the proactive resolution of exceptions such as a container shipping delays or missed delivery appointments.

According to Infor, Nexus helps manage over $1 Trillion a year in trade across 74,000 businesses, including 45,000 suppliers and 15,000 carriers.

Infor Nexus Transportation Sourcing

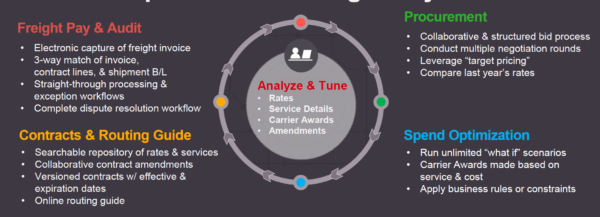

Infor Nexus supports 3PLs transportation sourcing with specific functionality for procurement, order management, rate management, shipment planning and execution, visibility, and settlement. As part of its 3PL solutions set, Infor Nexus works within a closed loop cycle. The goal is to optimize a 3PLs transportation spend via an optimal plan, ensure it is executed correctly, and ensure process improvements are continuously made within the system as needed.

Procurement is handled through a standardized bid process. After bids are received, users can run unlimited “what-if” spend scenarios and test negotiation strategies. Infor Nexus maintains a searchable repository of carriers; rates within a secure online routing guide. The Infor Nexus freight audit and pay process utilizes a three-way match of the carrier invoice, contract rates, and the shipment bill of lading to automatically process shipments for payment reducing manual entry and errors.

Infor Nexus Transportation Closed Loop Cycle

Infor Nexus Control Center

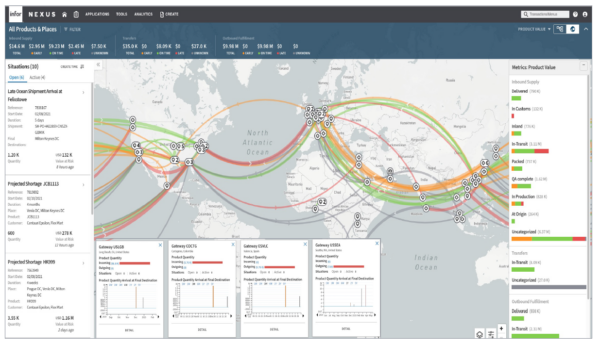

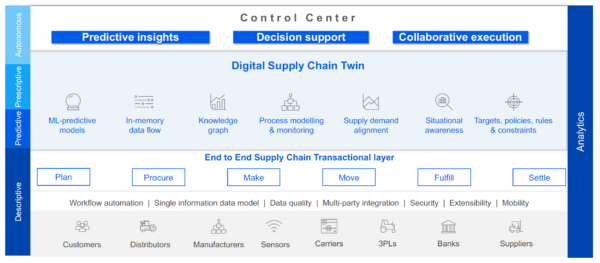

The Infor Nexus Control Center utilizes its proprietary Coleman Artificial Intelligence (AI) to extend its supply chain management capabilities across multiple business units, processes, and partners. Algorithms within the system can provide predictive alerts on potentially late shipments, real-time monitoring of supply and demand imbalances, and alerts for potential inventory stock outs. It also identifies underlying systemic issues that may present areas of opportunity and risk.

End-to-End Sense and Response

The Infor Nexus Control Center leverages advanced data science and AI to immediately identify and escalate issues without manual intervention, quantify and prioritize impacts, and prescribe optimal responses as events occur. A digital supply chain “twin” is leveraged to provide predictive options for advanced decision making and resolution. With a connected digital process, all business units and trading partners have immediate access to alerts and can carry out coordinated supply chain management within one integrated system. Expected transportation status compared to actual performance is continuously monitored including on-time service levels, inventory turns, and key cost metrics to continuously improve operational performance.

Intelligent and Responsive Supply Chain Capabilities

Infor Nexus’ Global Ocean Service

GT Nexus was founded as an ocean booking platform in 1999 and acquired by Infor in 2015. Over time, it expanded into an end-to-end visibility and international transportation management tool. Its supply chain visibility functionality includes live ocean GPS tracking, geo-fencing, and AI-based delivery prediction. Booking and contract analytics, carrier scorecards, and port and lane performance measurements are part of its functionality. Today, 95% of ocean carriers and NVOs are connected to Infor Nexus for visibility.

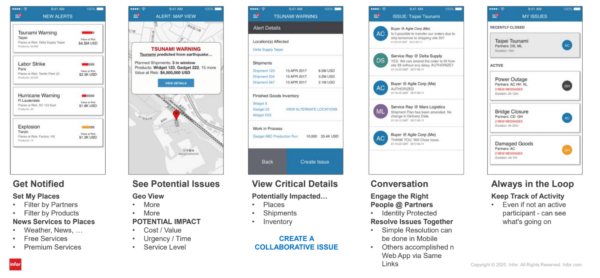

The Infor Nexus Ocean application has functionality for booking request generation and confirmation, container tracking milestones, management of electronic shipping instructions, bill of lading generation, alerts and exception management, and reporting. Shipping instructions are sent with Verified Gross Mass (VGM) container weight information. Users can configure reports, have them set on a scheduled delivery, or export them into Microsoft Excel. Within the mobile or browser-based application, users can monitor and manage exceptions and events. This includes weather alerts, order/shipment service issues, and provides a platform for conversations with trading partners. The Cargo-tracking function uses geo-fencing for timely transfer of inventory and improved planning at ports and with transload providers.

Collaborative Event Management

To ensure quality levels, monthly key performance indicators are tracked by carrier. Infor Nexus also has a built-in Carrier Awards Program. Providing 3PLs with the functionality to build strong carrier relationships is an emphasis at Infor Nexus. It has ongoing collaboration with 3PLs and shippers to address issues and develop technology solutions. Infor Nexus maintains a customer-driven “Shipper Council” network that heavily influences product development, design, data quality, and service improvements.

Digital Bid Management

Infor Nexus also provides customers with digital bid management capabilities. Procurement teams can use the application to evaluate and negotiate with over 15,000 carriers. After analyzing “what if” scenarios, teams can quickly view an optimal plan and interact with carriers on the system to negotiate, revise, and refine bids. Lane changes and updates can be made as needed throughout the year with active contract management.

Predictive ETA for Inventory

Accurate inventory visibility is a growing challenge and need within the industry. Late deliveries and delays can cause lost revenue; while early deliveries can build excess inventory. Infor Nexus’ Predictive ETA leverages its visibility management tools coupled with its transactional and milestone performance information to generate updated real-time inventory for inbound information for planning. Infor’s machine learning models mine through its vast network of data including over-the-road transport legs, global transit times by lane, as well as individual port dwell times to identify potential service issues.

Allport Cargo Services Leans on Infor Nexus for Greater Transparency and Collaboration

Allport Cargo Services (ACS) https://www.us.allportcargoservices.com/ is the North American subsidiary of Cargo Services Group, a Hong Kong-based 3PL serving over 100 consumer goods companies and retailers across 100 countries, operating 5.5 million square feet of warehouse and distribution space, and managing more than 1.5 million TEUs and 200,000 metric tons of air freight.

ACS’ customers are greatly impacted by port congestion, late ship unloading, and demurrage. Whether it be a unique issue in the Suez Canal or a backup in the Port of Los Angeles, ACS utilizes Infor Nexus for visibility to identify impacted vessels. Within the Infor Nexus business intelligence feature, ACS can view containers and shipments down to purchase order level details and provide visibility eight to ten weeks in advance of receiving. This information is shared with customers who can make decisions to pivot to alternative delivery modes such as air freight to meet delivery schedules.

Another issue faced by 3PL providers such as ACS, is that geo-fencing can provide visibility to vessels, but they might be anchored. Infor Nexus Predictive ETA provides visibility to the terminal level for ACS, increasing live visibility and decision-making capabilities.

ACS also utilizes Infor Nexus’ contract sourcing tool, to provide rates and costs to customers as a neutral partner. Customers see rates and costs applied to shipments down to the item level and can compare actual expenses against plan to measure performance. This feature allows ACS to understand landed costs and customers to see the direct impact of decisions made or changed.

Per ACS, a high level of value is obtained from the shared continuous improvement benefits with customers utilizing the platform. In addition, the Infor Nexus platform has allowed ACS to promote open relationships with beneficial cargo owners and carriers to accomplish the same goals, fulfilling customer orders as efficiently as possible.

Infor Nexus and ACS Value of Co-Partnerships

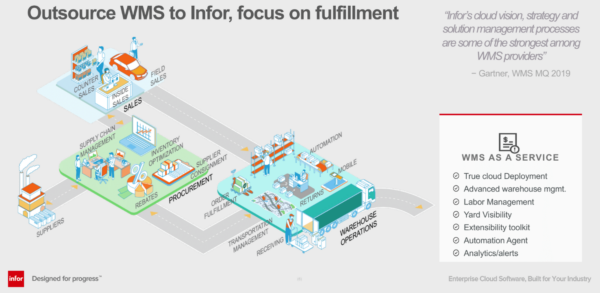

Infor WMS

Infor WMS is used by over 1,000 global customers in 50 countries, with 14 languages supported. Industries leveraging Infor WMS include Third-Party Logistics, Retail, Consumer Goods, Food and Beverages, Automotive, High-Tech, Healthcare/Pharmaceuticals (including Cold Chain), and Industrial Manufacturing.

Snapshot of Infor WMS Customers

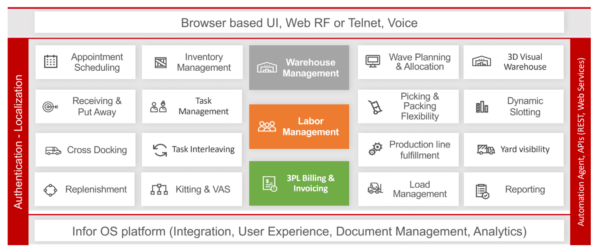

Infor WMS combines advanced warehousing, including the maximum utilization of inventory, space and labor using configurable rules all within one system. Inventory management allows 3PLs to optimize fulfillment for multisite/multiclient operations. Infor WMS can use RF technology or voice execution for the management of warehousing tasks including picking and put-away.

Infor WMS Fulfillment

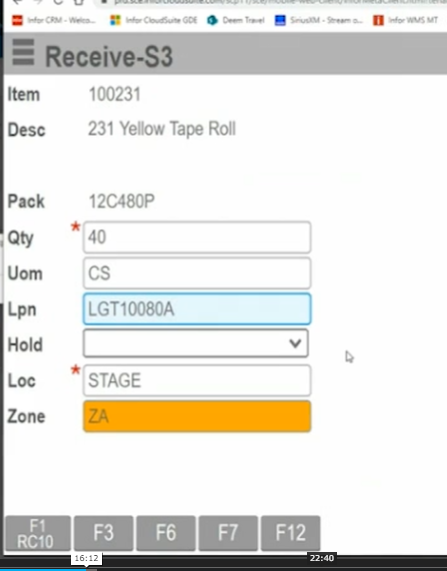

Within Infor WMS, 3PLs can streamline dock door appointment scheduling, directed put-away, returns management, and cross-docking/flow-through operations. Picking and dynamic replenishment for bulk inventory functionality are provided in the WMS. Configurable stock rotation rules and license plate (LPN) tracking, as well as visibility down to bin and each level are utilized to reduce obsolescence. Automated triggers improve stock rotation and space utilization. Wave and task management functions include highly configurable release and escalation rules to improve cycle times and balance labor workloads. Conveyor automation and pick-to-light can be tied into the system as well. The Infor WMS automation agent with built-in APIs, pushes out warehouse tasks to workers and receives confirmations once completed.

Infor WMS Capabilities

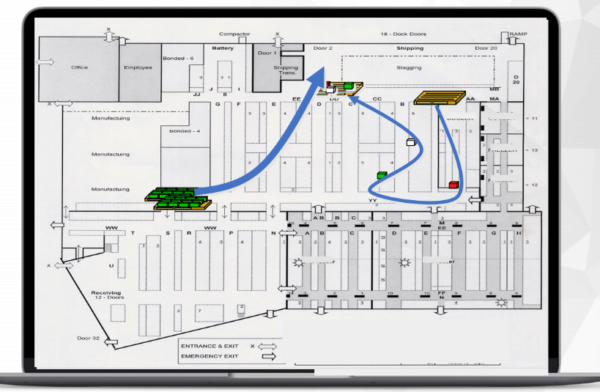

Infor WMS utilizes embedded, interactive 3D visual warehouse technology. Users can view workflow, bottlenecks, and at-risk inventory to initiate corrective actions within the WMS. The 3D visual warehouse technology arranges historical, active, and aged tasks with color heat indicators. Management can add key metric goals for tasks and measure standards against actual performance. Travel path and bottleneck analysis can be viewed in real-time and used to optimally re-slot inventory within the warehouse.

Immediate Insights with 3D Visual Warehouse

Usage of the strategies feature within the Infor WMS allows users to automate the put-away process. Receiving can scan product, receive and license plate handling units, and automatically put away the inventory based on rules and constraints pre-configured in the WMS. Lots, manufacturing dates, and expiration dates can be tracked in the WMS along with the shipment details.

Infor WMS Receiving Details

Intuitive picking wave management functions allow customers to manage business-to-business and direct-to-consumer fulfillment from a single facility. Inventory management can vary from first-in-first-out to last-in-first-out. Units of measure and other product attributes can be adjusted as needed. Infor WMS has built APIs to multiple small parcel shipping/manifesting systems.

Infor WMS Wave Planning and Allocation

Customer billing is also embedded within the WMS. It includes activity-based customer-level costing, billing, and invoicing functionality to improve revenue accountability and cash flow. In addition, account-specific pricing requirements, and pricing for value-added services in multiclient operations is also included.

The Infor WMS can be onboarded quickly. Its rapid onboarding process and configuration cloning allows customers to ramp up quickly and turn individual customer requirements into value-added solutions. Value-added services such as light manufacturing, kitting, and compliance labeling can be configured for customers. Other external systems that Infor WMS integrates with include ERP or legacy order management systems and Transportation Management Systems (TMS) from vendors such Manhattan, Blue Yonder, Oracle, and SAP.

Infor WMS Improves Future Supply Chain Solutions’ Inventory and Labor Productivity

Future Supply Chain Solutions Ltd. (FSC) www.futuresupplychains.com is a fully integrated third-party logistics provider in India. Its customers are primarily in the Food, Apparel, High-Tech, Automotive, and Pharmaceutical industries. It has 89 distribution centers and an express logistics network with 13 hubs and 126 branches. FSC had space and storage constraints for its diverse customer product mix. Complications also arose from serving customers in both B2B and B2C channels. After deploying Infor WMS, FSC was able to increase inventory accuracy to over 99.9%, shelf management improved 15%, and labor productivity increased 22% according to Infor.

Summary

Infor Nexus provides an end-to-end order, shipment management, and transportation procurement solution for ocean, air, and road transportation. Its Infor WMS solution helps 3PLs and shippers manage warehouse storage, handling, and value-added services driving leading inventory management and order fulfillment operations. The platform offers greater visibility along the supply chain as well as opportunities to better manage exceptions while assessing costs and related operational performance impacts. In an industry where disruption seems to be the norm, Infor’s technological solutions provide agile supply chain management to 3PLs and their trading partners.

Sources: A&A Primary Research, https://www.infor.com