Unyson Logistics becomes a Contender

St. Louis, Missouri USA

January 11, 2010

By

Evan Armstrong

Key Personnel:

Donald Maltby – Executive Vice President

George Jones – Vice President, Sales and Marketing

Shirley Lane – Vice President, Finance and Administration

Mick Noce – Vice President, Engineered Solutions

Brian Alexander – Senior Director, Operations

Erin Atherton – Senior Director, Solution Services

Tom Krenning – Senior Director, Operations

Art Nourot – Senior Director, Pharma and Procurement

Unyson Logistics Overview

Unyson Logistics was founded in 2004 as the non-asset based transportation management division of Hub Group Inc. Unyson’s annual revenues have grown over 30% for the last two years and it now manages approximately $750 million in transportation spend. Unyson has a staff of 100 based at its St. Louis headquarters and 17 onsite personnel supporting key customer accounts. Unyson also has operations in Burnsville, Minnesota managing Pharmaceutical Services. Unyson sales and leads are generated by Hub’s national sales network which has been cross-trained on Unyson’s service offering.

Much of Unyson’s customer base has been solidified over the past four years using process reengineering and a network transportation management approach that is attracting large and mid-sized shippers. Unyson’s customer base is concentrated in retailing, manufacturing, and pharmaceutical vertical industries. Key accounts include: Big Lots, The Home Depot, General Mills, Pfizer, Rexam, WD-40, and Western Container Corporation.

Information Technology is a Vital Service Offering Component

Unyson’s daily operations rely on i2 Technologies transportation management systems—TMS (supported by Nulogx Inc.) to provide tier-one transportation planning and execution functionality. In addition, Unyson uses i2’s Modeler and Strategist network modeling applications to analyze and reengineer customer supply chains. SMC’s CzarLite Bid$ense tool is used to help in managing carrier requests for proposals (RFPs).

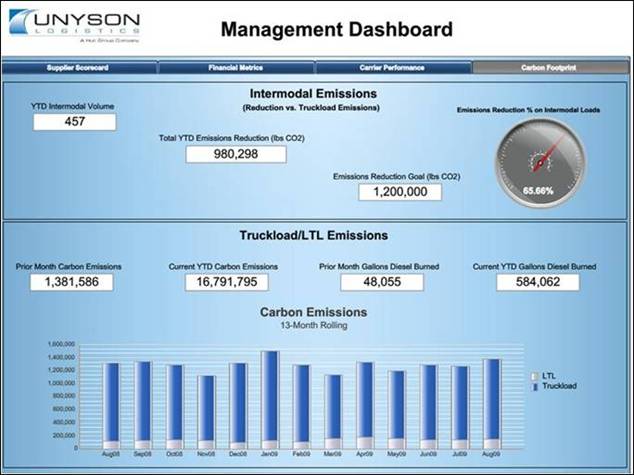

Unyson has also developed proprietary internet web based portals to interface with its customers and suppliers for online communication, reporting, and business intelligence. Unyson has also integrated a dock scheduling application to provide a comprehensive transportation management systems suite. Online customer reports are accessed at UnysonToolbox.com. This site provides customers with visibility to supplier performance metrics, carrier service levels, and detailed transportation savings analysis through a “dashboard” style interface. In addition, the site has screens detailing changes in a shipper’s carbon footprint to support ongoing “Green” initiatives. A screenshot of the carbon footprint dashboard is shown below.

Unyson Online Business Intelligence Carbon Footprint Management Dashboard

St. Louis Transportation Management Center Operations

As part of our visit, we were able to meet with Unyson’s major customer operations teams.

With a 14 person, three-shift, just-in-time transportation management operation, Unyson is supporting Coca-Cola’s domestic bottling operations. Unyson manages approximately 60,000 truckloads of Coke and Dasani water bottles annually for bottle manufacturers Southeastern Container and Western Container. The truckloads of bottles require inbound coordination to Coca-Cola’s filling locations. Each truckload is measured for on-time performance to the required delivery time with zero tolerance for error.

Unyson began managing General Mills’ multi-million dollar less than truckload (LTL) transportation spend in February 2008. Unyson provides General Mills with shipment status updates, management reporting, and resolves service performance exceptions.

One of the world’s largest specialty big box retailers has been working with Unyson for over four years and is its largest customer. Its annual transportation spend is $168 million and Unyson optimizes all of its inbound and outbound transportation to and from its five U.S. distribution centers (DCs) and two Unyson run crossdocks. In addition to consolidating LTL shipments into truckloads (TL), Unyson is also responsible for developing routes for the retailer’s private fleet trucking operation and building truckload continuous moves. The annual volume being optimized exceeds 175,000 orders and Unyson has a staff of 10 in St. Louis and five onsite at its distribution headquarters managing the operation. In addition to its supply chain network optimization and management duties, Unyson also performs dock scheduling at each of the network locations, supports store fixture buyouts and installations, and resolves any service performance exceptions.

To support the daily operations, Unyson’s five person carrier procurement team manages the ongoing carrier RFP processes for the majority of Unyson’s customers. Unyson recently ran a multiple customer LTL RFP for nine customers representing over $60 million in transportation spend. The RFP allowed the nine customers to generate significant savings.

The following customer case studies detail how Unyson has worked with customers in improving supply chain management operations.

Customer Case Studies

Rexam PLC is a leading global consumer packaging company with products such as trays and containers for use in beverage, personal care, healthcare, and food industries. It has 20 manufacturing plants and multiple third-party warehouse sites in its network. It is truly multimodal utilizing LTL, TL, IML, ocean, air, and boxcar rail transportation modes.

When Unyson began working with Rexam in 2008, carrier management, routing and freight payment was decentralized and shipment tendering was performed manually. Rexam selected Unyson to manage its daily transportation planning and execution, reduce its supply chain costs, improve shipment visibility, manage continuous improvement activities, provide strategic network design services, and support its Green initiatives.

Initially, Unyson performed LTL and TL carrier RFPs. This effort has resulted in significant savings for Rexam.

Next, a central Rexam operations team was established to provide daily transportation management services, a customer service call center, and freight bill audit and payment services. Unyson has also provided Rexam with continuous improvements including network design and analysis to provide recommendations for new locations

Oatey Company is a major plumbing products manufacturer. Approximately 90% of its shipments are from four plants in California, Ohio, Nebraska, and Texas. Prior to working with Unyson, all carrier management, routing and freight payment functions were decentralized and shipment tendering was performed manually.

Oatey selected Unyson in January 2009 to produce transportation savings by leveraging Unyson’s overall transportation spend versus its individual plant spends. Other key action items were to: improve supply chain reporting, identify key performance metrics, identify and manage continuous improvement activities, and integrate Oatey’s supply chain under one supply chain management system.

Unyson performed initial LTL and TL carrier RFPs for Oatey to reduce costs. It then implemented new carriers across Oatey’s network and began managing daily transportation planning and execution. In addition, Unyson manages inbound and outbound carrier routing compliance and performs carrier management and freight bill audit and payment services. Through its negotiations and process improvements, Unyson estimates that Oatey will realize over 22% in savings in its transportation spend for 2009.

Summary

Unyson Logistics is rapidly growing and is one of a select group of 3PLs with supply chain network management expertise. It has found a niche in focusing on large and mid-market customers with complex domestic supply chains. As companies continue to look for ways to reduce supply chain costs, outsourcing functions to 3PLs for improved network management is an increasingly prevalent strategy. With its operational and technology capabilities, Unyson Logistics will continue to benefit from this trend.

Sources: A&A Primary Research, https://www.unyson.com