Transportation Insight Expands its LLP Capabilities and Gains Market Traction – Lean Principles Drive Business Model of Continuous Improvement

Hickory, North Carolina, USA Site Visit

November 21, 2011

By

Evan Armstrong

Key Personnel:

Paul Thompson – Founder & Chief Executive Officer

Chris Baltz – Chief Strategy Officer

Laura Easley – Chief Solutions Officer

Reynolds Faulkner – Chief Financial Officer

Rick Brumett – Vice President, New Market Development

Todd Fain – Vice President, Business Development

Clay Gentry – Vice President, Logistics Operations

Eric Lail – Vice President, LEAN Performance Solutions, Total Insight

Chris Mendenhall – Vice President, Pricing Services

Charles Moore – Vice President, Parcel Services

Rod Poole – President, United Sourcing Alliance

Jim Taylor – Vice President, Technology

Rich Tracchio – Regional Vice President, Business Development

Josh Walker – Vice President, Organizational Development

Jay Wilson – Vice President, Processing Services

Transportation Insight Overview

Hickory, North Carolina headquartered Transportation Insight LLC (TI) was founded in 1999 and has developed into a major domestic transportation network manager with extensive lead logistics provider (LLP) capabilities. CEO Paul Thompson has built an experienced management team and total staff of over 200 associates. TI’s operations will manage over $1.4 billion in supply chain expenditures during 2011 and will generate gross revenues of $425 million with net revenues of $32 million.

TI takes a Lean Management approach to developing supply chain network solutions for customers. Its high-level solutions offering includes network transportation management, supply chain consulting and network design services, LLP contract warehousing, business intelligence reporting, and Lean Management consulting. Its core transportation management services include: carrier contract negotiation, transportation request for proposal (RFP) development, carrier routing guide development and compliance monitoring, web-based and/or fully-integrated transportation management system (Insight TMS®), freight bill audit and payment, loss and damage claims processing, and daily transportation network shipment planning and execution. TI is also currently developing international transportation management capabilities to augment its domestic offering.

TI acts as an LLP for virtually all of its major customers which include: American Tire Distributors, CARQUEST, DSI Systems, Havertys Furniture, hhgregg, Highland Products Group, and Snyder’s-Lance.

Transportation Insight CEO Growth and Vision Synopsis

During our visit, CEO Paul Thompson took the time to review TI’s past growth and share his vision for the future. Thompson sees TI’s ongoing growth and business model improvement in four distinct versions—“TI 1.0” through “TI 4.0.” According to Thompson, TI’s founding business model (TI version 1.0) focused on parcel and LTL (less-than-truckload) carrier sourcing and customer cost reductions. To support the startup operations, TI developed significant proprietary transportation management systems (TMS) components, all of which are still in use today.

After the first five years of operation, TI dramatically increased its IT investment, added full truckload transportation management capabilities, improved its business intelligence reporting capabilities, and added additional network transportation management services moving it to TI version 2.0. As part of version 2.0, TI deployed MercuryGate’s TMS for transportation optimization and daily shipment planning. The MercuryGate TMS integrates with TI’s proprietary system Insight TMS, and Cognos business intelligence and reporting system.

According to Thompson, “At this point in TI version 3.0 we have our core house in order.” TI began its version 3.0 in 2010. It has tripled the size of its inside sales group, increased its vertical industry expertise through key executive management hires, expanded its enterprise customer transportation management capabilities, further enhanced its business intelligence reporting/dashboarding, began LLP contract warehousing operations, added Lean Management consulting services through its subsidiary Total Insight, and has started developing international transportation management capabilities. It also unbundled its freight bill audit and payment services to support varying customer needs. Today, TI has over 400 long-term enterprise customers and is looking to add 150 enterprise accounts in 2012. TI is anticipating a greater than 25% sales increase in 2012 pushing it to around $550 million in gross revenue.

Thompson’s vision for TI version 4.0 includes full-scale international and domestic transportation network management, domestic warehousing, and an IT platform that can provide global supply chain visibility and business intelligence reporting and dashboarding. His long-term goal for 4.0 is to expand TI’s business to $3.5 billion in supply chain expenditures under management.

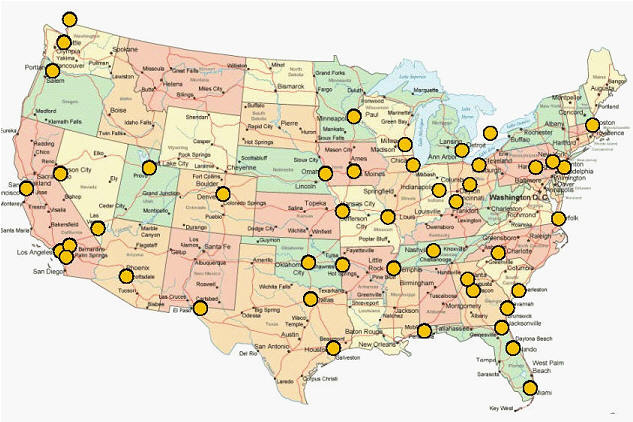

Transportation Insight LLP North American Warehouse Network

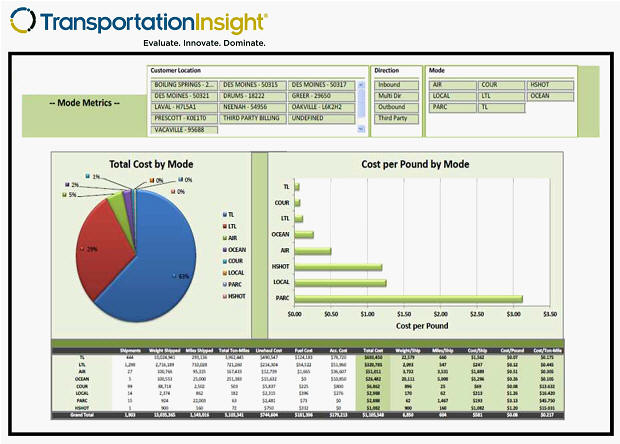

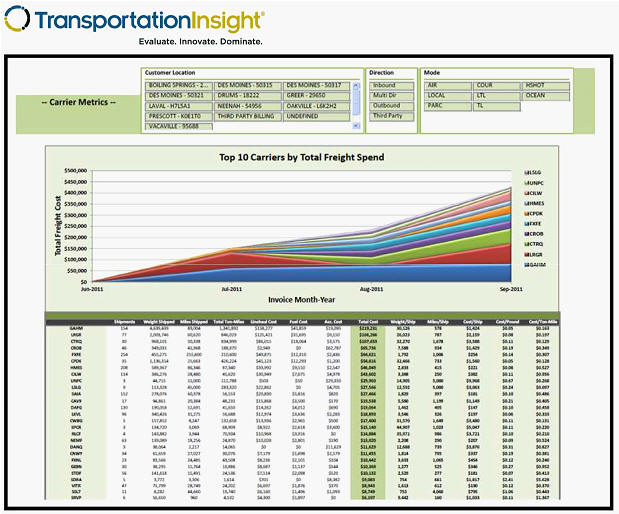

Transportation Insight Business Intelligence Reporting, Dashboarding and Scorecarding

TI’s business intelligence reports/dashboards offer a comprehensive range of transportation metrics that can be customized to offer several levels of drill down analysis. Examples include a summary of volume and cost information by mode, lane, vendor, carrier, company division and location. The company also offers customizable carrier scorecards/dashboards.

Total Insight Drives Lean Management

In February 2009, TI acquired consulting firm, Petra International, to provide TI and its customers with in-depth expertise in Lean Management principles and techniques. It has since been rebranded as Total Insight. According to Thompson, “Lean Management skills are core to what we do in optimizing supply chains for clients. We continue to focus on how Lean principles and practices (and Total Insight) support our internal initiatives, as well as our clients’ efforts in driving out waste and improving operational efficiencies.”

To date, Total Insight has performed numerous Lean Certification courses for members of TI’s management. The long-term goal is to permeate a Lean culture throughout TI’s organization. In addition to TI’s Lean training, Total Insight has provided significant consulting services to multiple TI customers, including Snyder’s-Lance.

For Snyder’s-Lance, Total Insight was engaged to work with its Charlotte, NC production team in developing “best” practices to reduce its potato chip bagging machine changeover times by 25% and improve operator safety. Total Insight worked with the production team in preparing a value-stream map of the current changeover work process and developing a “spaghetti diagram” to highlight the waste in the current process. After the initial analysis, Total Insight facilitated production team meetings for developing new bagging machine changeover procedures. After the new procedures were implemented, time trials were run to evaluate the new procedures against the prior work standards. The new process improvements resulted in a 53% reduction in bagging machine changeover times. This equated to a reduction of 583 hours of production time or 24.3 days of capacity.

The customer case studies below highlight additional examples of how TI is working with two other customers to drive out costs and improve operations.

Transportation Insight Customer Case Studies

DSI Systems

Founded in Iowa in 1984, DSI Systems is the largest distributor of satellite and consumer electronic equipment in the United States. It serves a domestic dealer network as well as fulfilling direct business-to-consumer orders. DSI is the only distributor with 1-2 day delivery service levels for products to over 95% of the U.S. population in its market.

DSI began working with TI in February 2006. It was looking for ways to reduce transportation costs through better shipment planning and optimization in order to better compete with big box retailers. In addition, DSI wanted help in analyzing its distribution network and order planning processes, and identifying ways to reduce loss and damage transportation claims.

Initially TI performed a carrier procurement event to reduce transportation costs. It also implemented freight bill audit and payment and claims management services. TI then deployed distribution network analysis, which has been ongoing. Initially DSI had 25 warehouses in its domestic distribution network. With the help of TI through better carrier management, improved product sourcing procedures, and ongoing network cost analysis, DSI has consolidated its distribution network into seven warehouses and dramatically improved its inventory management processes while maintaining its customer service order delivery levels.

To further improve its daily transportation management, DSI worked with TI in 2010 integrating its order management system with Insight TMS. Through the use of Insight TMS to consolidate shipments, DSI was able to reduce its parcel volume by 25.2% from 2010 to 2011. Through its relationship with TI, DSI has realized average annual transportation savings of 12.8% and has avoided additional cost increases totaling 8.2% per year through process improvements, administrative time savings, and forgone carrier pricing increases.

Highland Products Group

Headquartered in Boca Raton, FL, Highland Products Group is a Top 500 e-retailer, specializing in supplying a large number of indoor and outdoor furnishings to parks, schools, commercial, and residential properties.

Highland partners with over 150 vendors and coordinates direct drop shipments of products to customers in the United States. Highland selected TI in February 2007 to help it support its rapid business growth, improve its vendor order and inbound transportation management processes, and better manage its transportation margins.

TI initially performed a carrier procurement event to reduce Highland’s transportation costs. It also implemented freight bill audit and payment and claims management services. TI then integrated its proprietary shipment rating and carrier routing software with Highland’s e-commerce website to improve carrier routing compliance and to help Highland better manage its transportation margins. Today, when customers place orders online at Highland’s website, the TI system specifies the least-cost, best-service carrier routing and specifies the routed carrier on the vendor’s purchase order. On the actual ship date, vendors can tender shipments to carriers using the Highland/TI system. The system fully interfaces to carriers via EDI (electronic data interchange) for shipment status updates. By working with TI, Highland has been able to keep its customer service staffing to two people while growing at over 50% per year during its tenure with TI.

From its relationship with TI, Highland has accumulated average annual transportation savings of 15.3%. Using TI’s claims processing application, Highland has reduced the time spent processing freight claims from eight hours to 20 minutes per claim. Outsourcing claims management to TI has saved Highland approximately 1,150 administrative hours per year. In addition, through additional process improvements, administrative time savings, and forgone carrier pricing increases, Highland has avoided additional cost increases of 9.9% per year.

Transportation Insight Operations Summary

By applying a continuous improvement approach to transportation management, Transportation Insight has grown rapidly over the past 12 years. With a focus on staying ahead of emerging client needs, TI has expanded beyond its origins in LTL and parcel carrier management to full-scale multimodal transportation network management, TMS integrations, LLP warehouse management, Lean consulting, and advanced business analytics, and is now entering the international transportation management market. Its approach has been successful and the company continues to win new business.

Sources: A&A Primary Research, http://www.transportationinsight.com/