Shanghai New Jinqiao International Logistics Co., Ltd.

Shanghai, China Site Visit

August 2, 2013

By

Eric Xiang

Key Personnel:

Mr. Zhang Hao, Manager

Ms. Hong Bi, Development Dept.

Founded in 1994, Shanghai New Jinqiao International Logistics Co., Ltd. (New Jinqiao Logistics or NJQ) is a state-owned enterprise wholly invested by the Shanghai Jinqiao Group. It has 300 employees and manages five warehouses with 200,000 square meters of space in Shanghai for both regular and bonded warehousing. Regular warehousing is 66% and bonded warehousing is 34%. The five offices/warehouses are in Jinqiao, Yanshan, Waigaoqiao, Zhangjiang, and the Pudong Airport.

Its service scope is as follows:

- Warehousing: Regular and Bonded Warehouse Management

- Customs Declaration: Inspection and Declaration, Documentation

- Import/Export Trade: Procurement Distribution, Import/Export Agency

- Transportation: Domestic Transportation and Customs Supervised Transportation

Its warehousing and distribution services include:

- Spare/Service Parts Reverse Logistics

- 24-Hour Emergency Delivery

- Simplicity of Processing, Packaging, Sorting, etc.

- Goods Distribution

- Barcode Management

- Customer-Specific Operational Processes

- Online Warehouse Management System

New Jinqiao Logistics has a proficient IT team with a wealth of experience in logistics consulting and software development. Its modern information management system can handle all data flow and documentation. Using the system, New Jinqiao Logistics has achieved a paperless e-business and more efficient operations.

Jinhai Customs Clearance Industrial Co., Ltd., a subsidiary of New Jinqiao Logistics, has a good relationship with China Customs. The company has over 10 years of experience in customs declarations. Nearly 80 well-qualified customs personnel have extensive experience in providing high quality services to Fortune 500 companies.

Omron Case Study

Introduction

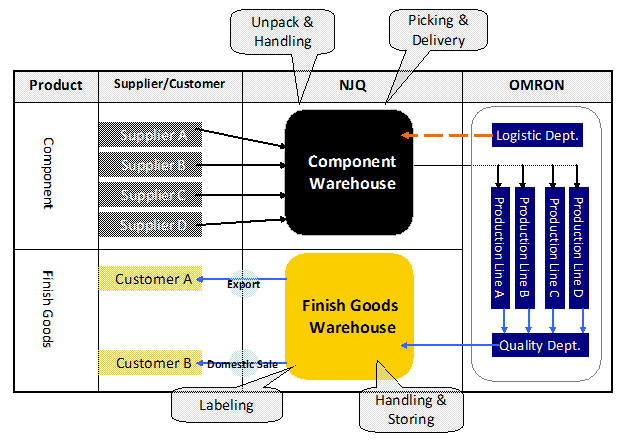

New Jinqiao Logistics provides just-in-time (JIT) warehousing and distribution services for Omron. A staff of 70, 12,000 square meters of warehouse space, and 18,000 spare parts are managed in the operation.

Challenges

- Storage management of parts received from suppliers

- Strong demand in the barcoding of parts

- Lack of experience in temperature-controlled warehouse management of electronic components

- Expanding goods type and volume

- Emergency spare parts handling

Solutions

- Goods are received, barcoded and onto the shelves within 24 hours

- 24 hours corresponds to the production line and distribution services

- Building a temperature-controlled warehouse to ensure the long-term storage of electronic components

- Information processing services and real-time queries

- Emergency items completed within one hour of delivery on the production line

Case Model

Benefits

- JIT logistics services largely reduced lead time

- The adoption of vendor management inventory (VMI) prompted suppliers to reduce inventory levels

- VMI cut nearly all logistics costs for Omron before products hit Omron’s production line

- Integrated logistics services and contact with VMI suppliers simplified the whole supply chain for Omron

In addition to warehousing, distribution and customs declaration, New Jinqiao Logistics provides both air and ocean freight forwarding to meet customers’ demands. However, freight forwarding is not a big part of its business.

New Jinqiao Logistics has an import/export license, which provides convenience to its customers and spurred gross revenue growth.

New Jinqiao Logistics’ customer base includes some Fortune 500 companies and many local trading companies as well. Logistics companies also rent warehouse space, which balances costs.

New Jinqiao Logistics is a good warehouse manager in Shanghai interested in cooperating with partners from overseas.

Sources: A&A Primary Research, http://www.jqlogistic.com/