SCI Group Builds Out its Integrated Solutions Offering

Toronto, Ontario Canada Site Visits

February 1, 2011

By

Evan Armstrong

Key Personnel:

John Ferguson, President & CEO

Paul Ragan, Senior Vice President of Operations

Steve Phinney, Senior Vice President of Corporate Services

Ann Pompilio, Vice President of Finance and CFO

Chris Galindo, Vice President of Business Development & Marketing

Sean Watson, General Manager of Transportation

Yvan Bourbonnais, General Manager of Progistix

SCI Group Overview

Since its founding as Progistix in 1996, SCI Group has grown organically and through acquisitions to become one of Canada’s largest third-party logistics providers. For 2010 it is on track to generate $150 million in revenue. SCI has built a business with approximately 70 long-term customers and has a staff of over 1,200 employees. Through its combined operating companies, SCI Group has developed significant value-added warehousing and distribution capabilities and has recently expanded its transportation management service offering. Its major customers include: Amazon.ca, Bell Canada, Lowe’s Canada, Rogers Communications, Shared Services Southeastern Ontario (3SO), Siemens, Toys“R”Us, and Xerox. SCI Group’s major growth milestones are detailed in the figure below.

SCI Group Growth Timeline

SCI Group’s Progistix and SCI Logistics subsidiaries manage 13 warehouses located in major Canadian metropolitan areas with over 1.5 million square feet of space. Key value-added warehousing and distribution services provided to customers include: dedicated and multi-client warehouse management, spare/service parts logistics, reverse logistics, inventory management, kitting, packaging, and supply chain network design and planning.

The Group’s First Team Transport operation is a niche critical parts domestic transportation manager. It is on track to manage over 200,000 shipments in 2010. Over 25% of the shipments it transports are for same-day delivery. It also provides specialized transportation and “white glove” product installation delivery services.

SCI Group and Related Companies Integrated Solutions Organizational Approach

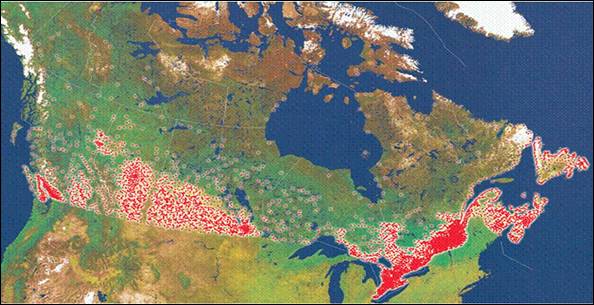

SCI Group works closely with sister company Purolator (Canada’s largest courier) and other members of the Canada Post Group of Companies to develop integrated solutions for customers with complex supply chain needs. Its combined operating network provides customers with significant coverage in remote areas as shown in the figure below.

SCI Group and Related Companies Logistics Network Operations

Bell Canada Lead Logistics Provider Operations

SCI Group’s integrated capabilities are highlighted in the logistics solutions set it has developed for Bell Canada. Out of its dedicated 300,000 square foot Signet Drive operation in Toronto, SCI is performing considerable value-added warehousing and distribution services for Bell. These include the outbound fulfillment of parts and equipment orders to over 12,000 Bell wire line service technicians throughout Ontario and Quebec. SCI is managing over 9,000 stock keeping units of goods in over 18,000 bin and rack warehouse locations, performing tests and repairs of DSL (digital subscriber line) modems and high-tech equipment, programming equipment, providing customized telecommunications wire and cable cutting, and performing kitting services.

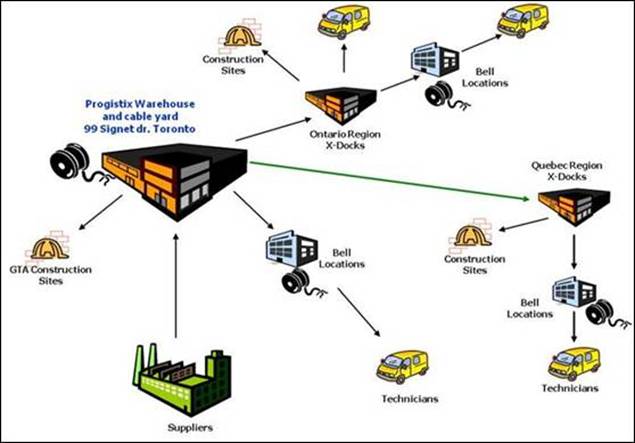

The outbound Bell wire line technician distribution operation performs deliveries to construction sites, 100 Bell locations, and utilizes Ontario and Quebec crossdocks to further consolidate and deconsolidate orders for final delivery. Technician orders received by 7 P.M. are guaranteed to be delivered by 7 A.M. the next day to points in Ontario and Quebec. The basic network flows are shown in the figure below.

Bell Canada Technician Network Management Operations

To support the network operations, SCI manages a dedicated 27 person 24/7 call center in Montreal to process technician orders, manage product return authorizations, and administer product warranties. Approximately 125,000 calls/requests are handled by the call center each year.

The Signet Drive Toronto operation uses SAP WM for its WMS (warehouse management system). The operation’s main measure of work volume is order lines processed and it is fulfilling Bell technician orders for approximately 850,000 order lines (at approximately 3.5 lines per order) per year. The operation is performing cluster picking for up to 24 orders at a time using voice picking hardware interfaced to the WMS. RF (radio frequency) devices are used for put away and inventory replenishment. Because of the picking variability, picks are made to carts and totes versus the use of primary pick modules. Cycle counts are performed by SKU (stock keeping unit) and the operation is currently running at 99.95% picking accuracy and 99.74% absolute inventory accuracy.

As a value-added service, SCI runs a 23 person cable cutting operation and manages a supporting 10 acre outdoor cable yard. The cutting operation utilizes five cutting machines and cuts approximately 35,000 indoor wire and outside telecommunications cables per year. Specifications are supplied by Bell Canada and the wire and cables ordered can be from less than one meter to 10,000 meters in length.

SCI also performs a DSL internet modem/router kitting operation for Bell Canada. Most of the outbound kitted product is distributed to Bell technicians for final installation.

Five people working in three shifts, process approximately 50-60 technician and customer returns per hour. Product disposition is determined on site and determinations are made by SCI to refurbish or resale products. SCI is performing refurbishment work which includes the reprogramming (“flashing”) of cable top boxes. It is also testing returned internet routers.

SCI recently began to provide services to Bell for a new market entry, IPTV (internet protocol television). In addition to the programming, the two person operation will test the boxes, assign serial numbers, kit the boxes with accessories and collateral materials, and fulfill outbound consumer and business orders.

One of five cable cutting machines

DSL internet modem/router testing station

SCI’s Canadian Ecommerce Fulfillment Operations

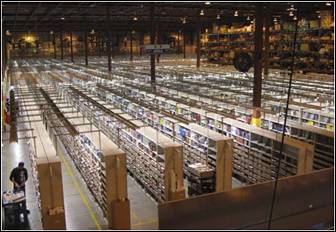

A short drive from the Toronto Bell Canada operation, SCI Group is managing a 181,000 square foot warehouse providing ecommerce fulfillment services to Toys”R”Us Canada and a leading

Bin and shelf storage locations

Toys“R”Us gift wrapping station

e-tail customer. SCI has been managing the facility since 2002. The warehouse runs 24/7 and has over 120,000 prime pick locations and over 650,000 active SKUs in inventory.

The Toys“R”Us operation began in 2008. SCI provides inventory management, order fulfillment, gift wrap, and transportation management services.

Key to both customers’ operations is SCI’s ability to scale up its fulfillment operation during the peak retail seasons. This includes quadrupling its staff and adding physical capacity. SCI has developed solid relationships with temporary staffing companies and a comprehensive training program and compensation plan.

To support the operation, both customers are on SCI’s SAP WMS interfaced with RF scanners for picking and put away. Wave picking is RF directed and done to carts. There is little full case picking; most is individual items.

In total the operation has 48 pack-out stations and 24 gift wrapping stations. Labeling and poly-bagging value-added services are also performed for some products.

SCI Group Operations Summary

As the customer operations above highlight, SCI Group has significant value-added warehousing and distribution capabilities. In conjunction with its sister company Purolator, and the Canada Post, SCI’s Canadian logistics network is wide-ranging. It is readily apparent how the combined operations can be bundled to expand business in developing additional value-added warehousing and distribution, spare/service parts logistics, and reverse logistics solutions. Its integrated service offering strengths continue to make SCI a leading Canadian 3PL.

Sources: A&A Primary Research, http://www.sci.ca/