Ryder’s Operation Management Centers

Novi, Michigan USA Site Visit

October 4, 2012

By

Richard Armstrong

Attendees:

Stephen Dean – Senior Vice President, Sales & Marketing

David Tisdale – Logistics Manager, Transportation Management, TMC North

Tony Williams – Logistics Manager, Operations Management Center

Ryder evolved its Operation Management Centers over the last 30 years starting with a concentration on inbound parts and materials support for automotive customers. As a result, processes and procedures are tight and perfection is the normal way of doing business.

Today services are provided for 34 well-known customers with long term relationships. Eight are OEMs (Original Equipment Manufacturers), 13 are Tier 1 automotive suppliers and 13 are non-automotive customers reflecting Ryder’s expansion into other verticals like retail.

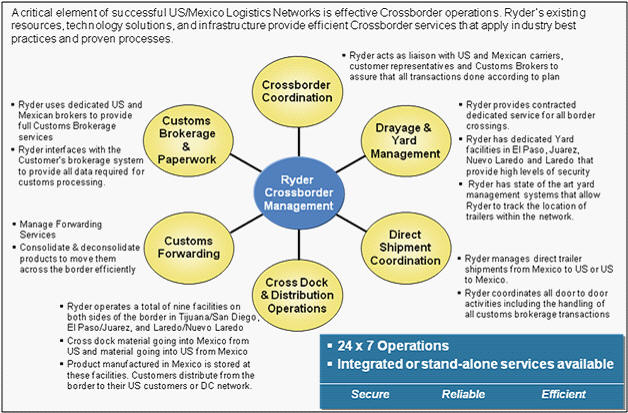

Ryder’s OMCs plan and manage 90,000 loads per month for its customers. Operations are 24/7/365. A unique, robust segment of OMC operations involves cross border shipments to and from Mexico. Ryder has managed cross border operations for over 25 years updating them regularly. The average time for moving a Ryder load is less than two hours, which is significant given the complexities involved.¹

Ryder’s OMC specialists work at two control centers. Seventy are in Novi, MI. Twenty-five are in Nuevo Laredo, Mexico. The operations are ISO 9001:2000 Certified and Ryder’s Mexican Customs Broker (Dicex) is on site.

Cross Border Management Services Overview

Ryder’s web-based LMS (Logistics Management System) is the primary tool for OMC personnel. Starting in 2003, Ryder built LMS to clearly and quickly take care of load management. Basic LMS modules are:

- Logistics Planning

- Contact Management

- Release Management

- Data Management

- Execution Management

- Load Monitor

- Shipment Request

- Manage Location Lists

- Operations Center Search

- Load Manifest

- Daily Manifest

- XMS User Guide

- ACA Monitor

- Premium Monitor

- LTL Monitor

- Issue Management

- Time Tracking

- Destination

- Dedicated Contract Carriage

The ACA Monitor routine allows for adding, cancelling and adjusting. LMS tracks key events – departures, arrivals, border crossings and special in-transit activities. The Premium Monitor routine is used for expedited and unplanned truckloads. Ryder handles a significant amount of premium business in support of manufacturing operations.

Dedicated Contract Carriage is a long standing Ryder capability used extensively, especially for Tier 1 customers. Planned route DCC operations, including milkruns, utilize over 100 drivers a day.

Less-than-truckload (LTL) Freight Management has grown steadily in recent years. Electronic data interchange (EDI) feeds and network optimization are standard features.

The Novi OMC operation shares space with Ryder’s logistics engineering and freight bill audit and payment operations. Logistics engineering has 200 employees doing transportation planning for OMC and TMC operations. Ryder’s TMC is located in Fort Worth, Texas. The TMC handles most outbound transportation management activity exclusive of Mexico.

Carrier Performance Management allows for proactive control by Ryder on its customers behalf. Carriers are normally long term partners. Their activities are measured and reported regularly through web access.

Customers have access to regular reports with spend and volumes, by plant and overall activity.

_________________________

¹Ryder and Laredo – Smooth Crossings, June 25, 2012, https://www.3plogistics.com/Ryder_6-2012.htm.

Sources: A&A Primary Research, http://www.ryder.com/