Associated Global Systems (AGS)

A Master of Niches

San Francisco, California USA

October 27, 2009

By

Richard Armstrong

Key Personnel:

Norman Freeman, President

James Tucci, Executive Vice President

Scott Richter, Vice President Global Supply Chain Solutions

Anthony Vella, National Call Center Director

Bernard Quandt, Director International Sales and Service

David Miller, Chief Information Officer

Fred Ruffalo, Director

Shawn Mack, District Service Manager

Pat Spillane, Vice President Business Development

Who do you call when you need:

- The displays to be delivered Saturday night at 9 PM?

- Your shipment to be on the next flight out?

- Your palletized machine with a guaranteed delivery in Dallas at 3 PM on Wednesday?

- UPS/FedEx type service but your computer exceeds their dimension limits?

- White glove home deliveries of high-end decorative items?

- Reverse logistics and reclamation on medical machines?

AGS has developed to meet these niche requirements where UPS, FedEx and less-than-truckload (LTL) carrier services stop.

Norman Freeman started AGS in 1958 as a domestic and international air freight forwarder. Over the years he has continued to specialize in doing what other companies would not. As standard practice, AGS provides personalized and customized services.

At its simplest, AGS’ services divide into transportation management and supply chain programs. Transportation services are primarily air based and range from next flight out to scheduled ground service within the U.S. One-half of AGS customers use it for same day services. Ninety-five percent use AGS for time definite ground shipments.

Figure 1 – Transportation Services Provided for Top 50 Accounts

Supply chain programs involve reverse logistics of high-tech devices and machines, product merge in transit, home delivery and value-added warehousing.

AGS operates from 60 U.S. locations. Thirty are company owned and 30 involve exclusive agents and drivers. Principal offices include San Francisco, Los Angeles, Chicago and New York. AGS offices are fairly small in size. However, the number of offices provide for good U.S. coverage. For example, Chicago has 16 employees. The warehouse is 35,000 square feet. Chicago handles domestic and international air and ocean shipments. Ocean shipments are full container load (FCL) and less than container load (LCL). Employees are assigned to specific import and export functions. AGS import and export activities involve extra value adds to insure customer satisfaction. As part of this, Chicago handles a significant amount of time definite and next flight out business. I visited Chicago, the New York customer service center and San Francisco to get a feel for AGS’ operations.

Figure 2 – Business Sectors of Top 50 Accounts

To give you an idea of some of the commodities involved, Chicago handles computers, slot machines, DVD cleaners, routers, switches and fixtures. Many shipments are heavyweight air and a lot of white glove delivery is performed. A good example of Chicago operations is a major logistics project for Hewlett-Packard in which new machines are being installed in branch locations for a major bank nationwide. AGS delivers the new ones and removes the old ones. Other return and reclamation customers are Pitney Bowes and Sims.

In addition, Chicago, like AGS Las Vegas, is a major terminal for trade show exhibits. AGS services GES, Freeman and other major trade show organizers. AGS is very familiar with McCormick Place which is the main location for most big Chicago shows. Chicago works very closely with the Minneapolis office which supports Best Buy. AGS primarily handles fixtures and promotional materials for Best Buy.

San Francisco has seven office personnel and nine warehouse associates. It runs nine trucks doing delivery and some pickup work. San Francisco has several typical AGS style accounts. One had signage and store fixture deliveries to a major retailer scheduled for Saturday night delivery and Sunday introduction to customers. For Smith & Hawkins, AGS provides home deliveries of furniture. Regular pickups are made for Restoration Hardware and Design Within Reach. Shipments are forwarded to AGS terminals and directly to customers across the U.S.

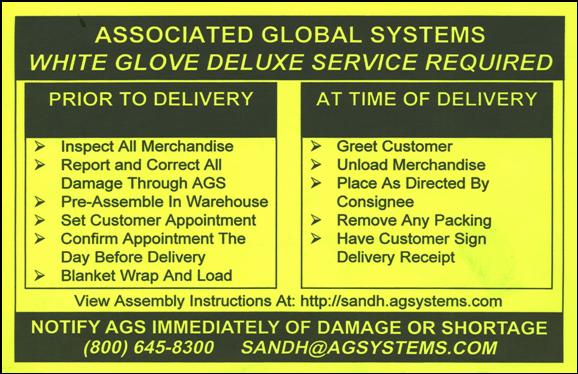

Figure 3 – AGS Delivery Sticker

At the time of my San Francisco visit, AGS was busy, on a national basis, with the delivery of servers to U.S. Census locations. Also, a monthly nationwide blast distribution was underway to 3,000 auto parts locations for a major auto parts importer.

The AGS terminal locations are supported on a 24/7 basis by the Customer Service Center (CSC) at the New Hyde Park, New York headquarters. The CSC operates three shifts with Tuesday–Saturday and Sunday–Thursday work weeks. Most of the staff have been employed by AGS for more than 10 years. The call center takes care of expediting, hot shipment tracking, reroutes, rate quotes and general problem solving. Vella indicated to us that AGS’ transportation business domestically was 40% air and 60% ground. International shipments are 80% air. Vella and his team give particular attention to new accounts insuring that processes become a controlled routine.

Vella says, “A lot of people don’t know about us but we are very good at what we do.”

Sources: A&A Primary Research, http://www.awotglobal.com/