Value-Added Services Drive ModusLink Europe

Apeldoorn, NL and Brno, CZ Site Visits

March 21, 2013

By

Evan Armstrong

Key Personnel:

John Boucher, President and Chief Executive Officer

Scott Crawley, President, Global Operations, Sales and Marketing

John Heffernan, Regional General Manager

Petr Jurecka, Regional Director of Operations – ModusLink Czech Republic

ModusLink Global & Europe Overview

ModusLink Global Solutions (NASDAQ: MLNK) has approximately 3,700 employees deployed across more than 30 facilities in 15 countries within North America, Europe and Asia. Its operations process and ship 470 million units annually for more than 200 customers. With $740 million in total revenue for 2012, ModusLink ranks among the top quartile of global third-party logistics providers (3PLs). ModusLink’s total revenue is split approximately even across its Asia, North America and Europe operations. Due to extensive manufacturing support services, its cost of purchased materials and transportation comprise 60% of total revenue resulting in value-added 3PL revenue of approximately $300 million. Key ModusLink global accounts include: AMD, Cisco, HP, IBM, Lenovo, Microsoft, and Sony.

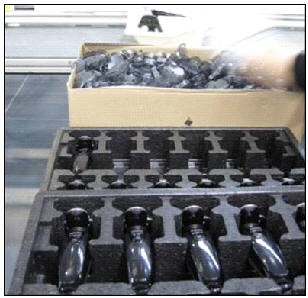

ModusLink operates in a Lean continuous improvement environment long on process control. Its global operations are ISO 9001:2008 certified, and the majority of operations are also ISO 14001 (Environmental Management Standard) certified. It has two facilities—one in Europe and one in the U.S.—that are ISO 13485 (Medical Devices Standard) certified. Through March 2012, ModusLink completed 987 continuous improvement projects over the past five years.

In Europe, ModusLink has five solution centers (value-added warehousing and distribution operations) located in: Brno, Czech Republic; Orléans, France; Jászfényszaru, Hungary; Kildare, Ireland, and Apeldoorn, The Netherlands. It serves 28 major customers from its European operations including: AMD, Cisco, GoPro, IBM, Lenovo, Nokia, Sony, TomTom, and Toshiba.

ModusLink Europe Solution Centers (Value-Added Warehousing Operations)