ModusLink’s Total Global Supply Chain Services

Riverside, California USA Site Visit

August 23, 2012

By

Kurt Baumann

Management:

Tom Nightingale, President, Sales & Marketing

Joe Jenio, Regional General Manager, Americas

Kenyon Blackhurst, Director, Business Management

Babak Naderi, Director, Operations & Engineering

Global Footprint for Value-Added Services Delivery

With $876 million in gross revenue in 2011, ModusLink Global Solutions (NASDAQ: MLNK) ranks among the top quartile of global third-party logistics providers (3PLs). Given its extensive Factory Supply services, the cost of purchased materials and transportation comprise 60% of gross revenue, resulting in value-added net revenue of $350 million. ModusLink has 3,700 employees deployed across 30 facilities in 15 countries within North America, Europe and Asia. Collectively, they process and ship 470 million units annually on behalf of 223 customers. Asian operations contribute 40% of net revenue with the remainder evenly divided between North America and Europe.

Core elements of ModusLink’s 3PL competitive advantage include the strategic location of facilities in major global distribution hubs, scalable and end-to-end supply chain services across a network of Solution Centers, presence in low cost countries and local market knowledge. Half of its Solution Centers are located in Asia with a long-term and significant presence in China. ModusLink has 11 facilities in the United States and Mexico, and 5 located across Europe. The headquarters of ModusLink’s global network is located in Waltham, Massachusetts.

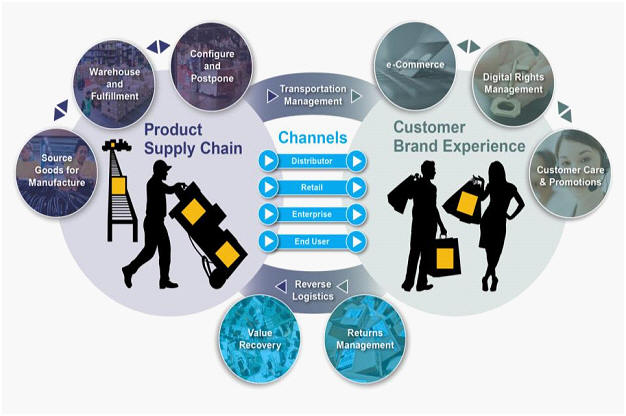

End-to-End Supply Chain Services

ModusLink designed its services portfolio to encompass a broad range of third-party logistics functions that are firmly anchored in value-added warehousing and distribution (VAWD) and fall into two categories. Traditional forward logistics operations for product supply are designed to serve multiple sales and distribution channels, including the distributor model, retail replenishment, B2B enterprise fulfillment, and B2C end-consumer delivery. Core value-added services within forward logistics are characterized by ModusLink as Factory Feed, which comprises demand planning, kitting and assembly, and supply base management and Postponement, which we describe in more detail below. Many of the customer products managed by ModusLink are relatively small, high-value goods, requiring time-sensitive distribution via parcel and less-than-truckload shipping, which represent the basis of transportation services.

ModusLink addresses the customer-interface and brand experience by providing e-Commerce fulfillment, customer care (via multilingual call center management) and loyalty programs support, and digital rights management for electronic licensing. These services account for less than 10% of ModusLink’s revenue.

Critical to its business model and utilized in both categories, ModusLink has developed essential capabilities to close the loop in the supply chain for its customers in the Technology, Healthcare and Retail/CPG industries by providing reverse logistics services, including return material authorization (RMA) processing, warranty repairs, value recovery, and refurbishment services. It is particularly adept at testing and repair of technological devices, and has designed efficient processes and procedures to manage a high number of stock keeping units (SKUs), bills of materials (BOMs), repairs and shipments. In its Bloomington (Indiana) Solution Center alone, ModusLink processes 4,500 RMAs daily, manages 15,000 active SKUs across 1,300 BOMs, and ships 90,000 repaired units on a monthly basis.

ModusLink’s Postponement Expertise

Postponement is a predominant practice among supply chain practitioners, such as to strategically deploy intermediate goods and accessories and delay final assembly and customization as close as possible to actual demand and within close proximity to end-customers. Labor intensive operations are often shifted to facilities in low cost countries. The practice requires the optimal geographic deployment of both inventory and value-added service capabilities. Supporting these decisions, ModusLink utilizes LLamasoft Supply Chain Guru software for modeling to determine the optimal network configuration for each customer and, in cases, specific product lines.

In addition to network redesign, ModusLink also provides engineering capabilities and product and packaging design. By using ModusLink’s packaging design process on one product line, Hewlett-Packard was able to eliminate over 88,000 pounds of packaging, which translated into $350,000 in cost savings and prevented the production of the equivalent of 62 metric tons of greenhouse gasses.

From our observations, it is apparent that ModusLink has put all the necessary pieces in place to enable Postponement, including analytical tools, services and capabilities, and physical infrastructure on a global basis. ModusLink provides a menu of services for Postponement that it

Examples of ModusLink’s Postponement services include:

- Loading the most up-to-date map content on GPS devices for TomTom;

- Pad printing text on remote controls for Universal Electronics that is unique to its end-customers; and

- Specialized packaging for retail display for customers, like Lexar, Cisco, Philips and AMD.

These services allow ModusLink’s clients to keep inventory at a more generic state until specific customer demand materializes and, thereby, minimized finished goods risk of overstock and obsolescence. Overall, it reduces inventory holding requirements as much as 40% and enables logistics cost trade-offs.

Riverside Solution Center: Returns Management & Warranty Repair

Riverside is a 360,000 square foot multi-functional facility located in southern California, in what is commonly referred to as Inland Empire. It serves multiple customers, including household names, such as Western Digital, Cisco and Universal Electronics, with a mix of forward and reverse logistics services. All totaled, Riverside manages 7,400 SKUs across 2,300 BOMs to build 21,626 assemblies and ship 74,000 finished goods units per day with 99.8% on-time shipment and 99.85% inventory accuracy.

ModusLink credits its high level of performance to robust quality control programs, IT automation, and a continuous improvement culture. Globally, all of ModusLink’s facilities are ISO 9001:2008 certified (Quality Management Systems). Most of them are ISO 14001 certified (Environmental Management Systems) and select facilities are ISO 13485 certified (Medical Quality Management Systems) based on customer needs. At the core of IT, ModusLink utilizes the full scope of SAP modules to support planning, procurement, production, quality, warehousing, distribution and business intelligence.

In 2007, ModusLink formally embraced Lean Six Sigma as the method for continuous improvement with an enterprise level program. Currently, 98% of its employees are Lean Six Sigma training. In 2011, they completed 987 improvement projects. Solution Centers visited by A&A clearly demonstrate the type of organization and efficiency of 5S workouts and application of DMAIC (define, measure, analyze, improve, control).

Riverside also serves some interesting high growth companies, such as GoPro. GoPro designs and sells high quality, wearable digital cameras. Its accessories allow attachment to surf boards, helmets, handlebars and all kinds of equipment. It’s a huge hit with athletes, especially adventure and extreme sports enthusiasts. In addition to forward logistics, ModusLink handles reverse logistics for GoPro cameras, which arrive in varying degrees of disrepair. Despite the appearance, many of the returned cameras can be refurbished. From those beyond repair, ModusLink salvages parts for re-use as B-stock inventory.

The total range of reverse logistics services provided to GoPro include RMA receipt, serialization capture, testing, refurbishment, warranty replacement order processing, and value recovery, using B-stock salvage and replenishment.

Upon repair or refurbishment, the GoPro cameras undergo the same rigorous testing that is applied to new units and ModusLink uses the same specifications. Upon approval, the cameras are kitted and packed for shipment, especially for warranty replacement, which generates cost savings for GoPro.

ModusLink is Well-Positioned to Add Value in Outsourced Supply Chain Relationships

With an increasing need to deliver an agile and responsive supply chain, ModusLink brings a range of capabilities that add value beyond simple logistics execution. Its ability to design and execute complex global supply chain processes from the point of manufacturing origin to consumption and returns has the potential to deliver differentiable value in an outsourced relationship, which it has aptly demonstrated in the Technology and Consumer Electronics verticals.

Sources: A&A Primary Research, http://www.moduslink.com/