Menlo Worldwide Logistics Extends its Network Transportation Management Reach

Aurora, Illinois USA

August 27, 2009

By

Evan Armstrong

Key Personnel:

Bob Bianco, President

Bob Bassett, Vice President of Sales and Marketing

John Beckett, Vice President – Aurora Network Logistics Center Operations

Tommy Barnes, Director of Transportation Procurement

Menlo Worldwide Network Logistics Center (NLC) Overview

While we have reported on many Menlo global warehousing operations over the past years, warehouse management is only half of the Menlo 3PL story. With a global transportation management staff of 374 serving 45 customers, Menlo managed approximately 3.3 million international and domestic transportation shipments in 2008. It is on track to manage $1.2 billion of transportation in 2009 and is targeting to grow its transportation management business to over $2 billion by the end of 2012.

A large amount of Menlo’s transportation is managed from its 150 person Network Logistics Center (NLC) operation in Aurora, IL making the NLC a significant player in domestic transportation network management. Approximately 83% of the transactions the NLC manages are for outbound shipments and 17% are inbound. Of the NLC transactions, 72% are for domestic shipments and 28% are international. Menlo’s key transportation management accounts include more recent customers Bayer MaterialScience, Dana, and the DTCI (Defense Transportation Coordination Initiative), and long-running Menlo customers Dow, HP, Starbucks, Ricoh, Sears, Electrolux, and Stanley.

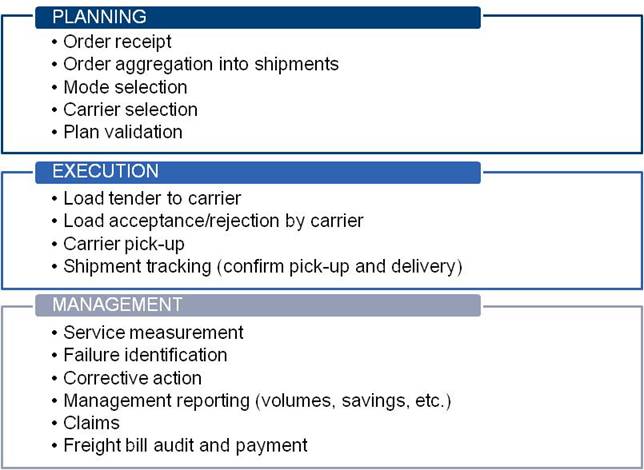

Menlo’s NLC utilizes a straightforward daily transportation management approach. Over 97% of orders are received electronically from customers via EDI (electronic data interchange), direct data feeds, or through manual order entry into Menlo’s proprietary supply chain management system dubbed “LMS” (Logistics Management System). The orders are then consolidated into shipments and the appropriate transportation mode is determined based upon shipment size and service requirements. From there, a primary carrier is selected based upon its cost, service performance, and operating territory. Once all of the orders are planned and the plan is approved by the NLC’s staff of approximately 70 load planners, shipments enter the transportation execution phase and are tendered to the respective carriers. Its basic process is shown in the figure below.

Figure 1 – Menlo NLC Transportation Management Process

The LMS handles both domestic transportation modes and international air and ocean shipping. It has multi-currency and measurement unit capabilities and provides for currency conversion. Secondary service for non-transportation partner fees (storage, customs, etc.) functionality has also been developed allowing the LMS to provide customers with total cost calculations for transportation and services at an order level.

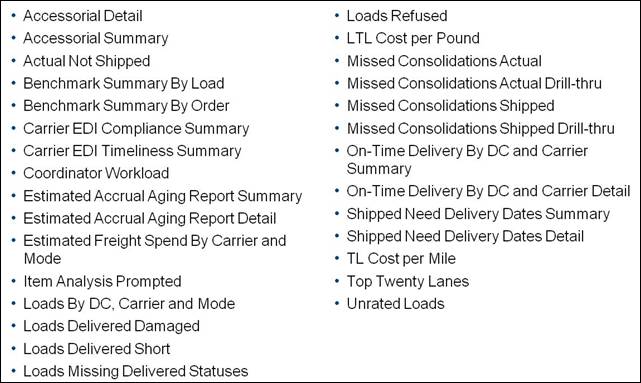

The LMS also has web applications for order entry, tracking and tracing shipments, event management, rate calculations, and carrier interfaces for load tendering. Additionally, to help better manage transportation functions, Menlo has developed a number of standard reports in its LMS, some of which are listed in the figure below.

Figure 2 – Menlo Standard Transportation Management Reports

NLC operations utilize multiple planning boards and numerous quality and productivity measures which are tracked each day and over time.

Menlo is driving “Lean” management principles throughout its organization and the NLC is no exception. Its customers are each supported by the Delivery Performance Team. The original concept for the team was developed some years ago by Menlo for HP. It works with customers and carriers to define a perfect order in the customer’s terms and manage its transportation processes in light of the definition. Each customer’s complete network (inbound and outbound) is analyzed and modeled on an ongoing basis to make process improvements.

Prior to daily transportation management by the NLC, it works with most customers in rationalizing their carrier networks. It uses the web based “EMPTORIS” procurement tool to structure single and multi-customer request for proposal (RFP) carrier procurement activities. The tool’s functionality allows Menlo to standardize carrier rate and cost structures, contracts, and develop standard agreed to performance metrics for its customers. Menlo is currently working with over 530 domestic and international transportation providers and is an active Environmental Protection Agency SmartWay transport partner.

The customer case studies below are good examples of the NLC/Menlo’s transportation management capabilities.

DTCI (Defense Transportation Coordination Initiative) Customer Case Study

In 2007, the United States Transportation Command (USTRANSCOM) awarded the Defense Transportation Coordination Initiative (DTCI) contract to Menlo. Menlo was contracted to develop, deploy, and manage an integrated transportation management program incorporating daily transportation planning and execution for all Department of Defense (DOD) material shipments moving in and out of continental US DOD facilities. It was a natural project for the NLC.

The DTCI rollout has been in multiple phases and when completed, the operations will encompass up to 68 DOD sites. The total freight under management will be approximately $1.6 billion over the contract life. Menlo is currently implementing Phases II & III which will be concluded in December. Upon completion, it will be managing shipments between 68 DOD sites. Approximately 72% of the shipments currently being managed by the 37 person DTCI NLC operation are less-than-truckload (LTL), 15% are airfreight, and 13% are truckload (TL) and specialized TL. To date, Menlo has realized gross savings of over 25% for USTRANSCOM through improved carrier procurement and carrier management. For example, it has been able to convert many air shipments to lower cost ground transportation providers.

Thus far the NLC is not systematically consolidating LTL to TL, but it will begin mode conversion/optimization operations in 2010 once Government systems can accommodate complex routing instructions. This should add significant additional savings.

Overall, the NLC operations are performing very well. Menlo has provided USTRANSCOM with on time pickups within eight operational hours of shipment tenders for over 98% of the shipments it has handled and has made on time deliveries on nearly 96% of the total shipments in the current period. In addition, small businesses are receiving 50% of the transportation spend through the initiative which greatly exceeds the contractual target of 23%.

Dana Customer Case Study

Dana is leading supplier of axles, drive shafts, and structural, sealing and thermal-management products to major vehicle and engine manufacturers in the global automotive, commercial vehicle, and off-highway markets. In 2008, Dana partnered with Menlo to reduce its logistics costs and improve transportation service levels for its US and Canadian plants.

Menlo deployed a centralized Lean Control Center, leveraging other Tier 1 suppliers. The solution incorporates Menlo logistics specialists co-located with Dana’s global logistics team in Fort Wayne, IN. Combined, this team exceeded savings and service expectations, which led to the expansion of the account one year later to include Dana’s Mexican logistics. The Mexican addition, based on-site at Dana’s Queretaro, MX location, along with a leveraged Menlo staff in Guadalajara, MX, supports daily execution of logistics plans engineered via Menlo’s engineering resources. Overall, Menlo through a lean foundation and its LMS system has developed a cohesive, information rich, solution for all of Dana North America.

Summary

With expanding European, Asian, and North American operations, Menlo has advanced to being a true Tier 1 major market supply chain manager. Its growing domestic NLC operations have been a critical component to its global growth. With its Lean management focus, Menlo has been able to attract significant new business even in the current recessionary environment. Its Lean approach is making Menlo especially attractive to high-tech, industrial, automotive and healthcare vertical industry customers.