Madden Logistics – Point-of-Purchase Mastery

Bloomingdale, Illinois USA Site Visit

December 21, 2015

By

Richard Armstrong

Key Personnel:

Larry Gundrum – Executive Vice President & General Manager, Madden

Bill Hendriksen – Vice President Operations, Madden

Andy Weidner – Director of Operations MCX, Madden

Madden Logistics Overview

Madden, founded in 1957, has roots as a printing company. It started in logistics in 1992. Madden focuses on point-of-purchase (POP) supply chain management. It has 300 total employees (82 in logistics). Madden has three facilities totaling approximately 650,000 square feet, all located within a few miles of Chicago O’Hare International Airport.

Madden primarily works with beverage companies (such as MillerCoors, Altria Group, Mike’s Hard Lemonade, and Bacardi USA). As an agency, it enables beer, wine and spirits customers to focus on marketing and growth, while it handles the packaging, distribution, warehousing, and transportation.

The Madden Method

Madden has built an integrated business platform utilizing a suite of five services that is designed to increase client focus on growing its business by eliminating complexity and costs from across the entire point-of-purchase supply chain.

The visibility and accountability created by this seamless integrated supply chain allows Madden’s clients to synchronize corporate activity with key stakeholders, integrate the POP process and optimize retail execution.

Client Services

The clients’ primary, single point of accountability is the Madden Client Services Team. The team encompasses the entire supply chain and brings a production, timing, logistics and execution perspective.

Clients gain a disciplined process and increased control and visibility, without having to manage it themselves. Madden helps with item development and production, bidding, supplier management and issue resolution. The results achieved from each dedicated Client Services Team includes leveraged company spend, predictable and consolidated store shipments, and improved retail efficiency and execution. Ultimately, this frees clients’ time to focus on its strategic planning and brand and sales growth. In addition, each beer, wine and spirits client has a dedicated distributor representative who develops solutions and best practices designed and refined with ongoing wholesaler input.

Technology

Madden’s technology is integrated into the entire process to provide visibility to all stakeholders enabling better informed business decisions.

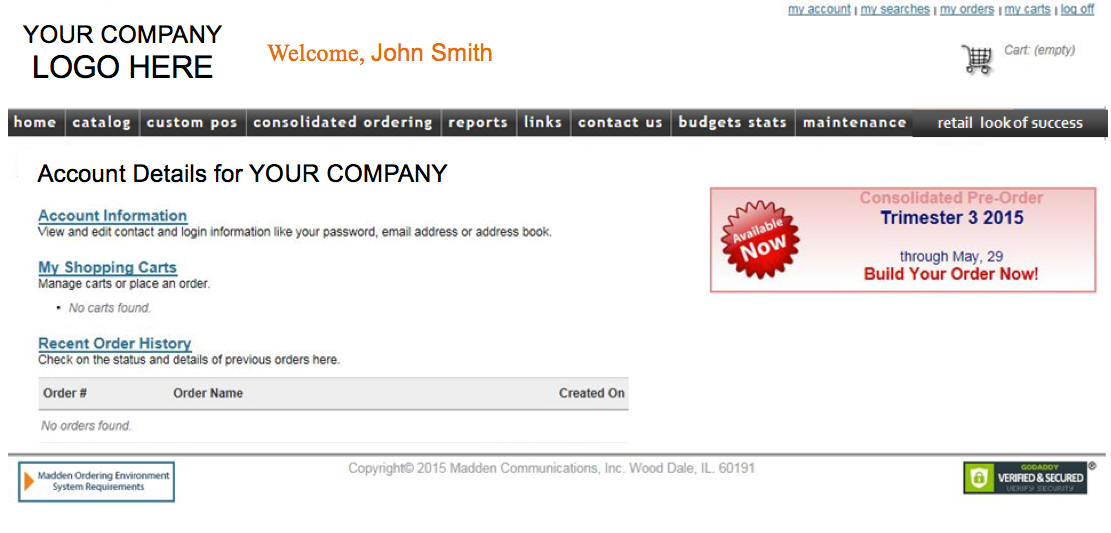

Ordering Tools

Madden offers integrated ordering tools through a singular portal for clients to access the retail objectives and look, order catalog and promotional inventory, create custom, print-on-demand items and update store profiles.

Workflow Management Tool

Madden’s ProMotion workflow management system allows 100% of all jobs and specific tasks to be managed and filtered by brand, project status and promotional program creating:

- 75% increase in compliance

- 75% reduction in duplication of effort

- 60% improvement in process best practices

Reporting

Madden provides over 20 standard reports on key areas of the business including:

Financial Systems and Reports

- Sales and use tax

- Price variance reports

- Summary invoices

- Shipped, not invoiced

Order History Reports

- Spend by company, brand, promotion, and item

- All extraordinary costs associated with each promotion

Warehouse Operations Reports

- Wholesaler execution

- Warehouse activity and cost

- Inventory activity

- Transportation key performance indicators and expenses

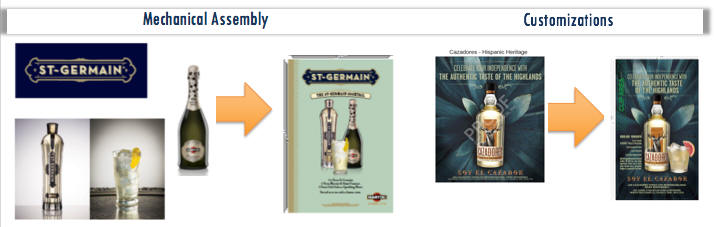

Studio Services

Madden Studio Services works directly with its clients’ agencies for the preparation of all final production files and is a resource for artwork customization and design concepts. The Client Service representatives and tools that support the creation of the marketing programs are the same representatives and tools used throughout the production. Clients maintain brand integrity, eliminate redundancy and cost and optimize the supply chain.

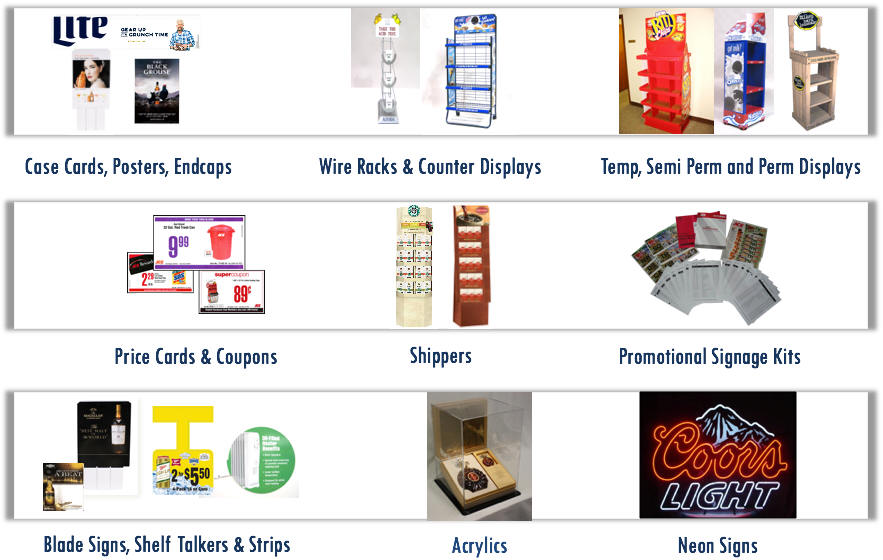

Print and Procurement

Madden utilizes a hybrid production model combining internal print capabilities with an external global network. This provides clients with speed and flexibility and a scalable model that brings the right solution with the right suppliers, all while synchronizing and leveraging spend and aggregating volume.

The flexibility and speed provided by Madden’s internal print facility becomes a competitive advantage for its clients because the capabilities are designed to optimize retail execution and capitalize on strategic opportunities by running across all buying teams and minimizing handoffs. Specific capabilities include lithography, UV, digital grand format, digital with inline finishing and other finishing capabilities.

Madden’s global Preferred Supplier Network (PSN) consists of approximately 250 suppliers, 40 of whom account for 80% of the spend with over $180 million of POP buying power. New client’s suppliers are vetted, and added to the PSN as requested, resulting in vested, long-term relationships. Madden secures financial controls through multiple bids, SSAs and defined savings metrics. Clients achieve process discipline without managing it themselves and realize an average procurement savings of 25%.

Success within the supply chain is built upon collaboration with suppliers and integrating controls into the process. Madden works with its supply base to establish a consistent set of quality expectations to match customer requirements and industry best standards. This focus applies to both external suppliers and its internal operations. Quality controls include: GRACoL G7 certifications, Sedex membership (AB), benchmarking, on-site assessments, audits, etc.

Logistics and Distribution

The Logistics and Distribution Teams are connected to the Client Service Team during the planning, development and production phases of brand marketing programs. Integrating logistics within the supply chain provides Madden’s clients the control and flexibility to deliver to the stores the accuracy, predictability and simplicity that they need. Following are recent results for Maddens beer, wine and spirits clients:

- On-time delivery (prior to retail start date) of 99.62%

- Quality control (including damage) of 99.99%

- Promotion consolidation rate of 99.70%

- Shipment accuracy measures at 99.99%

- Less than 1% expedited shipping for national programs to domestic distributors

- Inventory accuracy of 99.98%

Freight Optimization

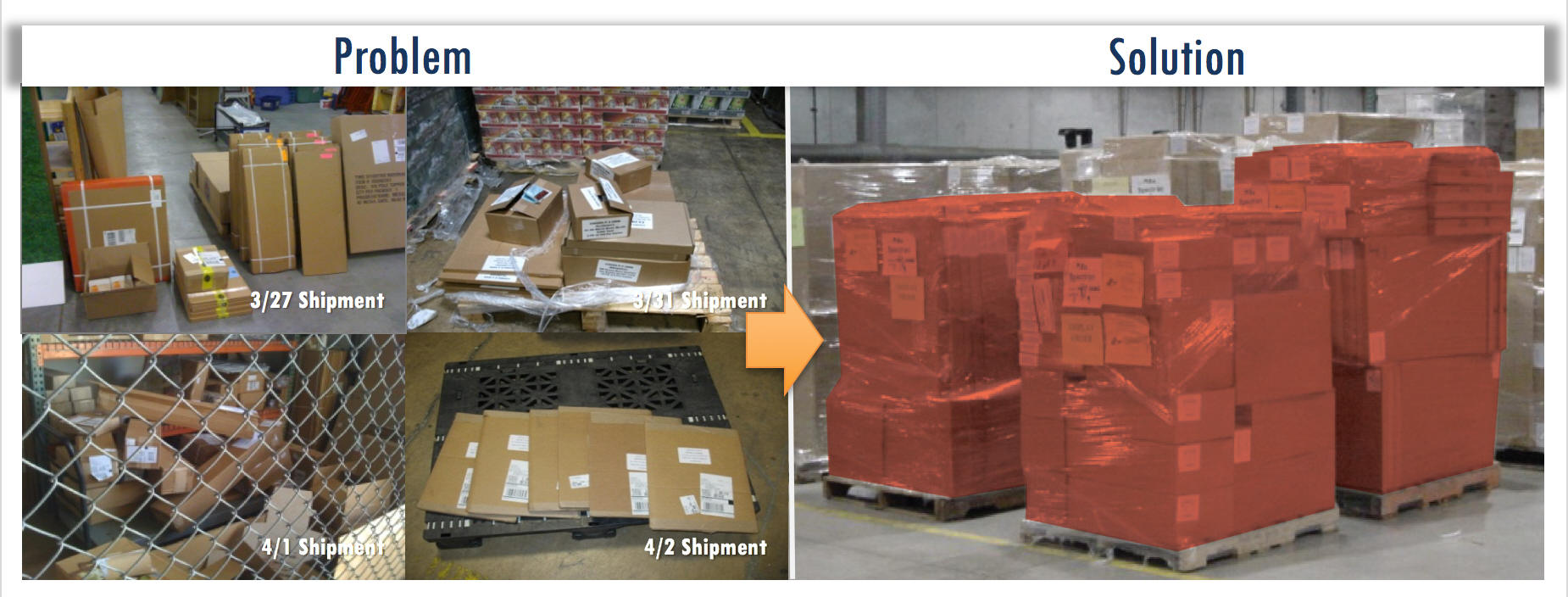

Consolidation

Madden has visited hundreds of wholesalers, participated in clients’ wholesaler point-of-sale (POS) council meetings and engaged in thousands of conversations all focused on finding ways for clients to become simpler to work with, to increase efficiency and to help wholesalers execute with excellence at retail. Its POS supply chain is focused on delivering one consolidated shipment containing all of its client’s promotional items. Consolidation creates a clear differentiation for Madden’s clients from its competitors. Promotional programs are wrapped in specific colors, clearly identifiable, accurately packaged and easy to execute.

Madden makes consolidated shipments to over 1,200 distributors on a monthly basis with over 99% on-time delivery and accuracy rates.

Consolidation is the process of combining virtually all promotional items into a single monthly shipment. To be successful, this requires coordination of every aspect of the supply chain so that all items arrive at the Madden distribution center with enough time to be consolidated.

Freight Aggregation and Pool Distribution

Madden aggregates multiple customer orders/programs under a single bill of lading, on the same trailer, bound for the same location. Aggregation provides additional transportation savings.

Pool distribution is provided to numerous destination points within a particular geographic region. Pooling is a cost effective strategy focused on optimizing the line-haul portion of shipments. Today, Madden coordinates all outbound consolidation – aggregated shipments for customers moving through any one of eight pool points (cross docks) set up across the country. Materials move through majority of the transportation cycle without being touched, providing for minimal in-transit damage and faster transit times.

Standard Practices

Advance Shipping Notification (ASN)

The ASNs detail all arrival information for promotional POS and provide tracking numbers to enable wholesalers to trace its shipments. The ASN communication arrives 2-5 days prior to delivery, allowing the wholesaler to plan and staff accordingly.

Electronic Order Confirmation/Detail

Electronic order confirmations are sent to each wholesaler containing images, descriptions and quantities of all items ordered. These files are uploaded into wholesaler systems, which improve speed to market.

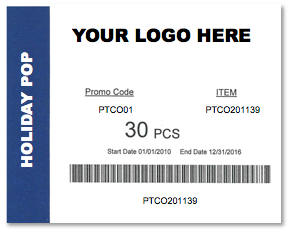

Brand Color-coded Labels

Color-coded labels make identifying POS by brand and program simple. Barcoded labels uniquely tie each package and its contents to a specific wholesaler.

Field Customer Service

The Madden Customer Service Team works directly with wholesalers and customer field sales forces. Being integrated into the supply chain provides visibility. From a resolution standpoint, 94% of all calls received are resolved within 15 minutes. Madden has full-time customer service employees dedicated to each account at its multi-client distribution facility.

Madden Logistics Operations Summary

Madden has become a master at controlling POP supply chains for 3-tier beer, wine, and liquor customers. The time is right for Madden to move to other verticals.

Sources: A&A Primary Research, http://www.madden.com/