LogiFlow – From Technology to 3PL

Davenport, Iowa USA Site Visit

September 24, 2018

By

Richard Armstrong

Company Background

In 2010, Executive Vice President for Dohrn Transfer, Joe Dohrn, thought he had a better idea. After watching the struggles his Fortune 100 customer was having with its existing technology and 3PL solution, Joe combined his career knowledge in transportation with his educational background in computer science and mathematics and began working on a technology solution. The technology he ended up developing started as a web portal that simplified the communication process between a large, complex supply base, carrier network, and manufacturing network.

After convincing the Fortune 100 customer to give the technology a proof-of-concept trial and the results came in, it was clear Joe was onto something. Building upon the initial success, Joe began developing additional features and functionality to support the customer’s complicated supply chain. Eventually, the technology developed into a fully functional, cloud-based integrated order fulfillment and transportation management platform.

Fast forward to 2016 and the winds of change were blowing. Pitt Ohio purchased Dohrn Transfer and Joe was given a choice–continue to oversee the trucking operations or make a run at starting a separate technology and logistics services company. Joe chose the latter and LogiFlow was born.

With a significant commitment from a Fortune 100 company to manage its North American transportation network, Joe went to work on developing new functionality and putting together a team to manage the transportation execution on behalf of the customer. LogiFlow was able to retain a few talented and key employees, Angie Purvis and Laura Huston, who were instrumental in helping Joe develop and implement the technology while at Dohrn Transfer.

Shortly thereafter, LogiFlow added some experienced and talented transportation management and technology professionals to support its operations and technology development efforts. Joe knew he needed immediate development support and tapped Mike Stroming, an experienced technology professional who was previously with Oracle. To oversee operations, Joe hired Mark Donovan as VP of Operations. Mark has a strong background in logistics from the shipper side of the table in the manufacturing sector. To help with strategy and growth, Joe brought Randy Mutschler on board as VP of Strategic Planning and Business Development. Randy is a veteran in logistics starting his career in the transportation industry, being a part of the birth of the 3PL industry in the 90’s, and then overseeing John Deere’s global logistics organization and operation with nearly $2 billion in spend.

Business Model – With a technology first approach and the option of logistics services to support the technology, LogiFlow offers a unique business model that competes with TMS/technology only companies as well as with traditional third-party logistics providers (3PLs). Today, LogiFlow is growing rapidly and its customer base includes multiple manufacturing and supply chain services companies with complex inbound, outbound, and service parts operations. In addition, LogiFlow has demonstrated its versatility with a 3PL-type customer on the technology only side of the business. The company has a vibrant pipeline with both TMS only and traditional 3PL/TMS-type solutions.

LogiFlow’s Technology Platform

LogiFlow’s platform has great flexibility and depth. Its system philosophy is built around the user with automation and data accuracy as a foundation along with a “simpler is better” workflow approach. Screens, workflow, and dashboards are intuitive and easy to read and backed up by accurate data and business intelligence.

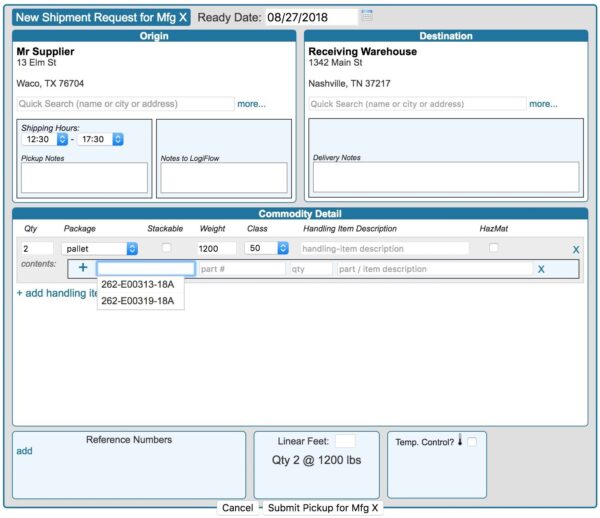

Supplier Portal – LogiFlow has received very positive feedback from the several thousand suppliers utilizing its web portal. LogiFlow receives electronic purchase order (PO) information from its customers that populates the system database. When suppliers are ready to ship, the system guides the user through the process and auto-populates the majority of the fields necessary to create and plan a shipment. The system also drives process discipline through automated alerts when suppliers are not in compliance with pre-established requirements. The following is a screenshot of LogiFlow’s highly automated supplier portal:

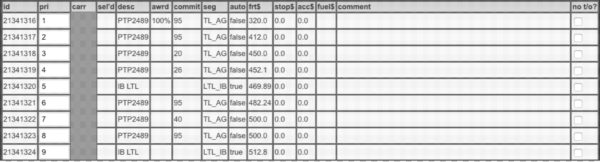

Rating Engine – One of the many strengths of LogiFlow’s technology is its proprietary rate engine. Joe’s extensive experience and knowledge in the LTL industry dealing with the complexities of hundreds and hundreds of different rate programs with shippers, went into developing a rate engine that is flexible and executes with the highest degree of accuracy. There is a broad service network and rate library maintained on over 200 carriers. Communication between carriers and LogiFlow is highly automated. The following is a screenshot example of LogiFlow’s rate optimization capabilities:

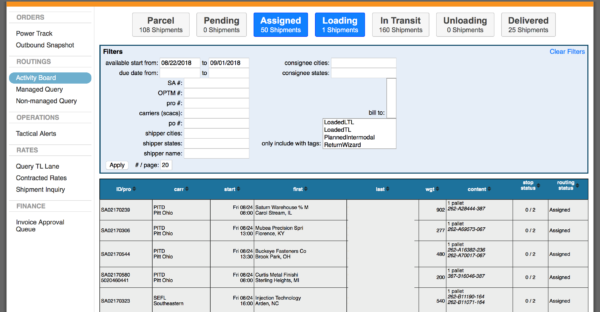

Visibility – Shippers today are searching for capabilities and advancements with visibility. LogiFlow has robust capabilities and offers a variety of visibility tools that provide information at the order, line, and/or shipment level giving its customers timely and accurate information. Following is a screenshot of one of the many visibility features within the LogiFlow platform:

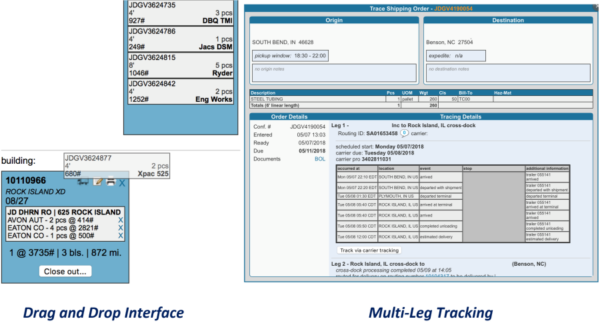

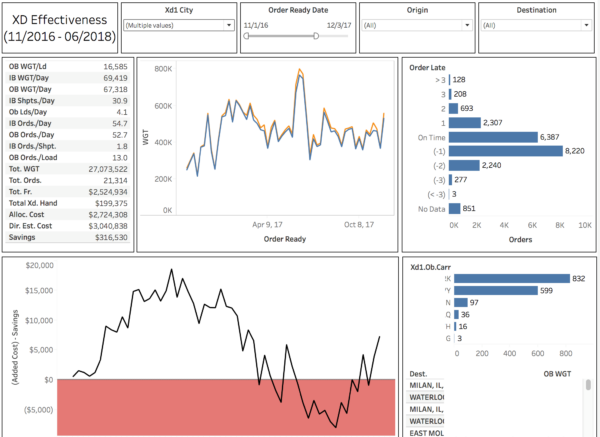

Optimization, Crossdocking, Pool Distribution, Etc. – Shippers with complex networks that require optimization functionality will find strong capabilities with LogiFlow’s platform. Utilizing Joe’s background in transportation, computer science, and mathematics, LogiFlow is rather unique in that it actually creates customized algorithms for optimization. Its Fortune 100 customer touts documented cost savings that exceeds $6 million through its technology. It’s important to note that LogiFlow replaced another industry-leading transportation management system so it demonstrates the power of customized vs. out-of-the-box algorithms.

Multi-modal crossdocks have always created multiple execution, visibility and cost management issues for shippers and 3PLs. Again, using Joe’s industry knowledge, LogiFlow seems to have mastered these challenges with simple, intuitive tools that provide end-to-end execution, visibility, and cost management capabilities. Following are a few select screenshots that display the technology’s abilities with crossdocking, visibility, and cost management:

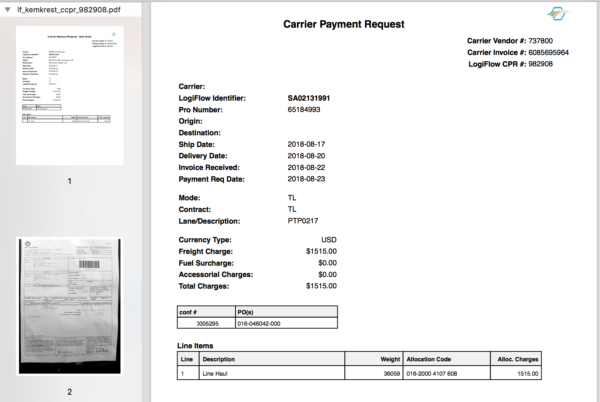

Financial Controls, Freight Audit and Payment – As mentioned previously, LogiFlow’s rate engine produces “to-the-penny” accuracy and that information feeds the freight audit and payment system. Once again, LogiFlow has a highly automated solution that matches electronic carrier invoices to shipment invoices within the system. When the carrier invoice and LogiFlow system information are in sync, invoices flow through without any human intervention (over 90%). However, when there isn’t a match, the system clearly identifies the discrepancy. LogiFlow then quickly identifies root cause and works with the carrier through an automated web portal to quickly resolve and apply charges and payments. Following is a screenshot of one of the many freight audit and payment features within the LogiFlow platform:

Summary

LogiFlow, with the support of a giant Fortune 100 manufacturer, is a tested and proven transportation management technology platform and logistics services company that is presently responsible for over 1.5 million transactions and $500 million in transportation spend annually. As a young startup, LogiFlow had to grow up quickly in order to meet its very demanding customers’ needs. Its keen focus on its customers has allowed LogiFlow to develop and deliver a sophisticated, highly automated, and comprehensive transportation management system.

With a unique business model, LogiFlow will be competing directly with established TMS companies in some cases and in other cases directly with 3PLs. Its management team has broad experience and knowledge on the transportation, 3PL, and shipper sides which has helped accelerate its service and technology offerings. Integration with the cloud-based technology is fast and easy, so the implementation of new customers is normally a matter of weeks.

With its capabilities, we expect LogiFlow to have accelerated growth to achieve, and possibly exceed, its goal of doubling in size by 2020.