Jacobson Companies Retools its Operations for Strategic Growth

Des Moines, Iowa USA Site Visit

November 2, 2010

By

Evan Armstrong

Key Personnel:

Brian Lutt, President & CEO

Peter Knapp, President – International Logistics Services

Mark Larson, President – Contract Logistics Services

Scott Temple, President – Transportation Logistics Services

Stan Schrader, Executive Vice President of Business Development

Scott Petersen, Director of Barilla Operations

Jacobson Companies Overview

Since the 2007 acquisition of Jacobson Companies by Oak Hill Capital Partners, it has merged operations with sister company Arnold Logistics, acquired international transportation manager Global Transportation Services, and restructured its business model for growth. The end result has been the creation of the third largest value-added warehousing third-party logistics provider (3PL) in North America* with integrated domestic and international transportation management capabilities.

Jacobson Companies (Jacobson) has recently restructured six operating companies into three integrated business units. Mark Larson is president of Contract Logistics Services (CLS), Scott Temple is president of Transportation Logistics Services (TLS), and Peter Knapp is president of International Logistics Services (ILS). In addition to restructuring its business units, Jacobson has made significant changes in how each business unit manages and develops customers across each of the operations; its new approach supports Jacobson’s goal of developing more end-to-end integrated supply chain solutions business. Combined, Jacobson generated total revenues of $628 million and net revenues of $447 million in 2009 with a staff of over 7,000.

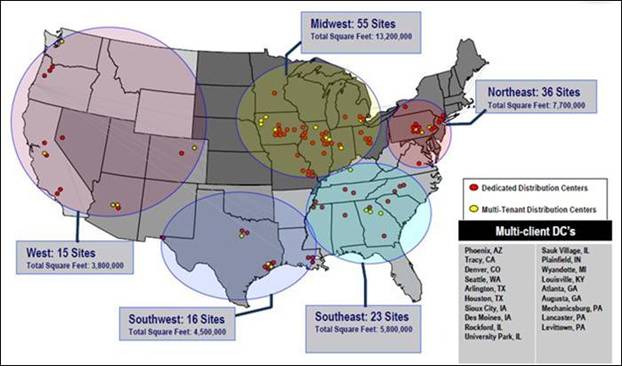

CLS has 145 warehouses with a total footprint of 35 million square feet. Its key services include: dedicated and multi-client value-added warehousing and distribution, secondary packaging and project management, contract manufacturing and manufacturing support, reverse logistics, short and long-term staffing, and supply chain network design and planning. To support its operations, CLS has a suite of supply chain management systems and uses Infor/Provia as its core warehouse management system (WMS). Like most 3PLs, it is also running a significant number of customer-owned WMS.

Jacobson Contract Logistics Services – U.S. Warehousing Locations

On the domestic transportation management side, TLS is managing over $550 million in freight and operates 585 power units and 2,800 trailers in its dedicated contract carriage (DCC) and over-the-road (OTR) trucking operations. Its staff of 836 work in both the non-asset and asset based operations. TLS services include: truckload transportation management for multiple modes, cross docking/pool distribution, DCC, less-than-truckload freight management, mode optimization, and freight bill audit and payment.

To support its non-asset based operations, TLS has developed its own proprietary transportation management system (TMS) dubbed “LINCS”. LINCS provides for order/shipment management from order entry through delivery and uses Infor/CAPS for its transportation optimization engine. TLS has integrated TMW’s TMS with LINCS to manage its asset based DCC and OTR trucking operations.

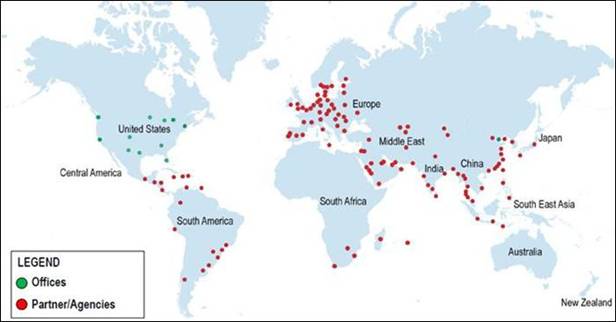

Jacobson’s ILS operations managed over 60,000 ocean container moves in 2009. ILS key service offering includes: air and ocean freight forwarding, shipment consolidation and deconsolidation, trans-loading, customs brokerage, combined sea/air programs, integrated international and domestic value-added warehousing, inland transportation management, and project cargo management.

In March 2010, Jacobson’s President and CEO, Brian Lutt hired Peter Knapp to be president of International Logistics Services at Jacobson. Like Lutt, Knapp was at APL Logistics where he served as vice president of Contract Logistics. He has extensive experience in the Asia-Pacific with APL Logistics and prior to that with DHL Exel Supply Chain. Knapp is in charge of growing the company’s global freight forwarding and international contract logistics service portfolio. Key to Jacobson’s growth strategy is developing a domestic Chinese value-added warehousing and distribution network as a way to tap into China’s rapidly growing economy.

Jacobson International Logistics Services – International Network Locations

As part of our visit to Jacobson, we had the opportunity to visit a warehousing operation for one of its key customers Barilla America, Inc. Its operation is detailed below.

Barilla America Ames, Iowa Dedicated Warehousing Operation

Jacobson has been working with Barilla America since 1998 and runs a 180,000 square foot dedicated value-added warehousing and distribution operation which is part of Barilla’s manufacturing operation in Ames, Iowa.

The warehouse is a national replenishment center and regional distribution center for Barilla. Jacobson is fulfilling approximately 40 outbound truckload orders of pasta and pasta sauce each day for Barilla and the complete warehouse inventory turns over every three weeks. Jacobson manages the warehouse with a staff of 30 (22 warehouse and eight management) running in three shifts 24 hours/7 days a week. The facility is very modern and has 35’ ceilings and 15 dock doors.

As product is produced and packaged, it is conveyed to the warehouse from manufacturing. Robots automatically build and palletize product. Once product is palletized, Jacobson personnel transfer the product into the warehouse. Product is typically warehoused for 24 hours or longer before shipping while Barilla performs product quality tests.

Product is stored in five-high drive-in racking in over 1,000 locations. Jacobson uses its Provia WMS integrated with RF (radio frequency) scanners to manage its warehouse operations. The system allows for directed put-away and solid inventory management including lot control. Most order picking is in pallet quantities performed within specified work zones and by order batches. In terms of value-added services, Jacobson builds store displays for Barilla, re-palletizes product as needed and runs five dedicated truckloads of product daily to Barilla’s remote warehouse in Ankeny, IA, in which Jacobson also operates.

To measure warehouse performance, Jacobson monitors approximately 15 KPIs (key performance indicators) in addition to the five major KPIs it monitors as part of its contract with Barilla.

In addition to the Ames site, Jacobson partners with Barilla in Des Moines, IA on packaging projects and operates a 156,000 sq. ft. distribution and value-added packaging operation in Avon, NY.

Jacobson Companies Operations Summary

With operations like those for Barilla and expanding domestic and international transportation management capabilities, Jacobson Companies has grown to be a leading domestic 3PL with considerable integrated supply chain management capabilities. By expanding its international presence and developing new markets, we anticipate that it will continue to achieve significant long-term growth.

*With 35 million square feet of warehouse space, Jacobson Companies is the third largest warehousing company in North America according to Armstrong & Associates, Inc. market research.

Sources: A&A Primary Research, https://www.xpo.com/