ATC Logistics & Electronics Drives Growth through Leading Edge Value-Added Services and Rigorous Process Control

Fort Worth, Texas USA

January 22, 2004

By

Evan Armstrong

Key Personnel:

Bill Conley – President

Jim Crawford – Vice President of Finance

Randy Engel – Director of Operations

Marc Sherman – Director of Information Technology

Three years ago it was hard to distinguish Aftermarket Technologies 3PL operation from their only customer AT&T Wireless. Today with new leadership and a reengineered business model, ATC Logistics & Electronics (ATCLE) is rapidly building business by exploiting the leading-edge capabilities it has developed to meet the needs of demanding electronics customers and the automotive customers of its parent company Aftermarket Technology Corp. (NASDAQ: ATAC). ATCLE now operates five ISO certified warehouses, yielded stand-alone net revenues of $114 million in 2002 (up 185% since 1998), and has over 650 employees. ATCLE core strengths are in high volume fulfillment and reverse logistics.

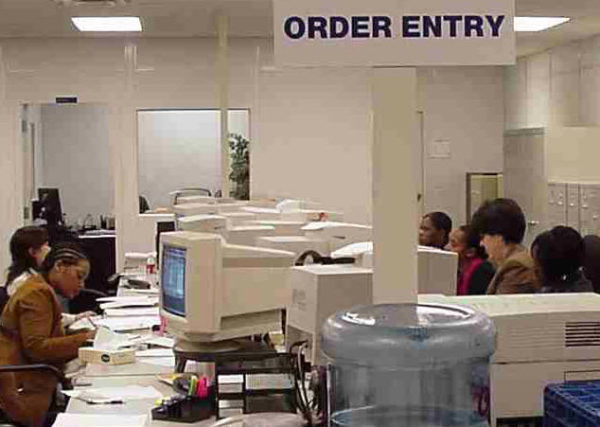

ATCLE’s main outbound distribution center (“NDC”) in Fort Worth has 224,000 sq. feet and is highly automated. The majority of the operation is dedicated to fulfilling new and replacement wireless phone orders for two of its major telecommunications customers: AT&T Wireless and Cingular. RedPrairie provides the WMS backbone and it’s LENS “dashboard” web interface is used to provide visibility. RF devices are used to capture item information and to direct all NDC tasks. Approximately 30,000 phone orders are shipped each day.