CEVA’s Houston Showcase

Houston, TX USA

March 15, 2012

By

Richard Armstrong

Attendees:

Matthew Ryan, President – CEVA Americas

Sam Slater, Executive Vice President – Domestic Operations & CEVA Ground

Steve Gundlach, Senior Vice President – Central Region

Nelson Bettencourt III, Senior Vice President – Domestic Product

Nate Reed, Managing Director – Houston

David French, Vice President Operations – CEVA Ground

Bryan Huckfelt, Vice President – Global Accounts

Bruce Hulings, Vice President – Energy Services

Kay Hart, Vice President – Marketing & Communications

Jim Quinn, Director – Truck Brokerage

CEVA’s CEO, John Pattullo, outlined a series of initiatives to us last fall that are being cascaded throughout global operations. CEVA’s Houston operations are a prime example of the success of these initiatives. Here’s the list:

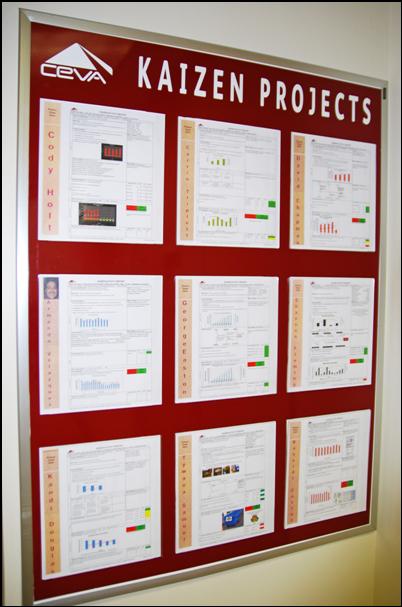

1.Program Uno – The “Number One” requirement is to ensure standardized business practices for all of CEVA’s freight operations. CEVA is continually updating its Matrix™ information technology capabilities to support Program Uno. In addition, LEAN quality practices, Kaizen, SMART Solutions for industry verticals and other quality methods are standard practice.

Since 2009, CEVA has been implementing a global program of measuring and qualifying each of its more than 1,000 operations. CEVA’s Site Classification Assessment (SCA) program defines required competencies within each of 35 operating metrics ranging from LEAN practices to customer satisfaction, financial performance and employee engagement. CEVA locations that have achieved the highest levels of capability and demonstrated consistency in these 35 areas can be awarded “Showcase” status. Showcase locations, like Houston’s Phase IV Energy Showcase, recognize personnel for a job well done and are toured by customers and other CEVA operators to demonstrate best-in-class principals.

2.Grow Century (Top 100) business by 60%. As reported in our “Who’s Who in Logistics” guide, these companies include a host of well-known global brands.

3.Increase the ocean freight forwarding business. CEVA was 12th globally with 783,378 TEUs (20’ container equivalents) in 2011.

4.Expand contract logistics (CL) offerings in profitable verticals and add CL solutions to complete supply chains for existing freight management customers. Houston has a number of customers who use all the CEVA parts for supply chain management.

5.Increase CEVA’s share of the China market by further building capability and leveraging its integrated global network to support Chinese companies’ globalization.

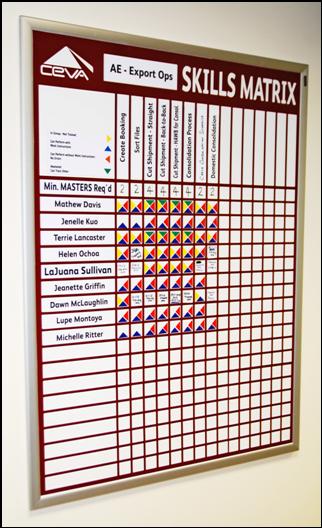

6.Organizational Capability – Equip CEVA’s people with the skills, training and development opportunities to support the company in its ambition to become the most admired company in the industry.

In response to corporate initiatives, CEVA has divided its Intercontinental Airport – Houston (IAH) operations into five phases corresponding to warehouse/office buildings. They are:

Phase I – 135,000 square feet (89,000 office, 37,000 warehouse). Phase I comprises the regional headquarters for CEVA in the Americas. It also manages a local delivery cross dock and staging for the outbound domestic transportation network. Fifty-two routes are operated from Phase I. Company equipment includes 8 vans, 42 straight trucks, 14 tractors, 58 trailers and 7 flatbeds.

Phase II – 102,000 square feet (10,000 office, 92,000 warehouse). Local sales is housed here along with import handling and contract warehousing.

Phase III – 96,000 square feet (half office, half warehouse). The domestic ground and CEVA Ground transportation network is housed in Phase III. The warehousing area is used for a major retailer’s distribution operation.

Phase IV – 132,000 square feet (20,000 office, 112,000 contract warehousing for Oil & Gas accounts). The office houses Houston’s international operations as well as the Energy sector team.

Phase V – 107,000 square feet (16,000 office, 91,000 warehouse). It is a dedicated contract warehouse for a major oil and gas drilling company.

There are approximately 800 employees on CEVA’s Houston campus. Summary statistics for Houston’s five phases are given in Table 1.

Table 1. CEVA/IAH Summary

| Space | Square Footage |

| Local Office | 49,000 |

| Warehousing | 380,000 |

| Secured Yard Storage | 481,000 |

| Total Yard | 748,000 |

| Shipment Type | Shipments per Year |

| Import Shipments Received | 301,000 |

| Export Shipments Crated | 51,000 |

| International Air | 36,500 |

| International Ocean | 10,500 |

| Domestic | 203,000 |

A host of domestic, North American, local, ocean, international airfreight, customs brokerage, transportation and contract logistics services are spread across the five phases.

Table 2. CEVA Houston Transportation Options

DOMESTIC/TRANSBORDER |

LOCAL |

OCEAN |

INTERNATIONAL AIR |

|

□ CHARTER |

□ DIRECT | □ DOOR TO PORT | □ DOOR TO PORT |

| □ NFO/SAME DAY | □ HOT SHOT | □ PORT TO PORT | □ PORT TO PORT |

| □ PRIORITY (NDay by noon) | □ REGULAR | □ PORT TO DOOR | □ PORT TO DOOR |

| □ REGULAR DAY (NDay by 5PM) | □ NEXT DAY | □ DOOR TO DOOR | □ DOOR TO DOOR |

| □ SECOND DAY | □ LIFTGATE | □ CUSTOMS CLEARANCE | □ CUSTOMS CLEARANCE |

| □ ECONOMY | □ TWO PERSON | □ FREE DOMICILE | □ FREE DOMICILE |

| □ DATE SPECIFIC | □ INSIDE | □ CHARTER | |

| □ NOW | |||

| □ PREMIUM | |||

| □ SATURDAY | □ VALUE | ||

| □ SUNDAY | □ DIRECT IATA | ||

| □ TRUCKLOAD | |||

| □ HOLD FOR PICKUP |

A host of domestic, North American, local, ocean, international airfreight, customs brokerage, transportation and contract logistics services are spread across the five phases.

Table 2. CEVA Houston Transportation Options

Nate Reed is managing director of Houston’s five phases. Approximately 75% of the employees in his organization are involved in Oil & Gas operations. CEVA is the largest Oil & Gas 3PL in Houston. Not surprising, Houston is CEVA’s largest Oil & Gas operation (about 70% of total traffic). CEVA’s penetration of this vertical is through relationships with drillers and drilling supply/support operations.

Bruce Hulings, vice president – energy services, has said, “Our customers include four of the six biggest offshore drilling contractors. On top of that, we serve 400 of the world’s 700 oil platforms. The energy sector accounts for a total of 6% of our turnover” (»$550 million).

In addition to Oil & Gas, which is largely international, CEVA has an extensive distribution business for a major high tech company that relies heavily on CEVA’s domestic transportation network. Additionally, CEVA provides a major retailer with extensive local and regional direct store delivery distribution (52 routes).

Key hub locations for CEVA’s Oil & Gas logistics are Houston, Singapore, Dubai, Aberdeen and Amsterdam. In Houston, seven acres on campus are used for outside storage of cable and other rig materials. Additionally, seven acres offsite are used mainly for pipe storage.

The domestic transportation network is served by seven hubs and 1,500 scheduled lanes weekly. The hubs are Chicago, Columbus, Dallas, Philadelphia, Atlanta, Los Angeles and Sacramento. The network comprises one of the largest Freight Management closed-loop networks in North America, and the only forwarder with its own ground network, providing infrastructure for both domestic and international shipments. Within the network, 2,000 power units varying from vans to day cabs to over-the-road tractors are used. Three thousand trailers are used. Controlled by the network but not tied to hubs are truckloads of which there are 400 to 600 per day in the system. Most (≥85%) of the power in the network is provided by owner-operator contractors. Employee drivers are used primarily in local operations (direct store delivery and phase-to-phase).

The domestic network supports Premium Domestic Services that include: expedited delivery, home delivery, events and fixtures, pool distribution, transborder services and reverse logistics management.

In addition, CEVA is one of the largest forwarders of airfreight in North America.

In summary, Houston operations are a fascinating mix of air, ground and ocean. Project logistics is a large part of the business. Running the domestic transportation network is the second major piece. Now let’s take a look at the individual phase activity.

Phase I

Fifty-two outbound routes operate from Phase I. (The previously-mentioned major retailer’s deliveries are done separately from Phase III).

At 4 A.M., the first inbound load is received from the Dallas hub. At 7 A.M., the first deliveries move out. Thirty-five to seventy-five residential deliveries are completed in a normal day. These include appointment and white glove activities. A majority of the work is managed by CEVA contractors. White glove deliveries are normally made by two-man teams. Customers of a large online retailer choose their own delivery windows and CEVA fulfills them.

All Phase I local drivers have an electronic mobile automated devices (EMAD) software application which connects to Houston’s local dispatch system. The application is used in place of paperwork and phones for communication, with the next version, being released next quarter, adding GPS capability.

Applying the 5S discipline of LEAN, the Phase I dock has a series of standardized bays with signs overhead and yellow lines the size of vehicle carry capacity painted on the dock. If freight overflows a dock space, a larger vehicle is assigned. The yellow lines are one of many visual systems throughout CEVA’s operations. In addition to local areas, there are bays for major hubs in the trucking network. 5S disciplines such as color coding, shadow outlines for tools, etc., are used to standardize workspace conditions and provide workers with immediate visual recognition saving time and effort. Continuous process improvement, Kaizen and LEAN are standard in Houston.

At Phase I, office employee performance meetings are held each day at 9:30 A.M. Performance and problems are addressed, reviewed and corrected. Employee meetings to maintain and improve quality are standard practice in all CEVA operating units.

Phase I reverse logistics includes asset recovery for electronic devices for major manufacturers.

The second major function at Phase I is outbound loading to the hub network. As part of this heavy use of the CEVA hub network, Phase I houses dedicated people assigned to Houston’s major outbound account, a leading high tech manufacturer. This major customer represents the majority of the non-energy business outbound from Houston. Bryan Huckfelt is responsible for this operation and is lead person for the Century (Top 100) account involved.

CEVA has 20,000 transactions a month for this global account. Some shipments involve fully equipped server rooms requiring movement on flatbed equipment. These shipments are delivered at precise times to installation teams. More often though, shipments are consolidated into the trucking ground network. Overnight air and next day air are used regularly. Brazil and South America have become strong markets.

Expedited linehaul is regularly provided using teams to hubs in Miami, Philadelphia, Chicago, and Los Angeles. These runs include combination, consolidated air services through the four major gateways and others as necessary. In a typical month, Houston has 17,000 outbound shipments and about half as many inbound shipments.

Phase I houses an x-ray scanner authorized by the Transportation Security Administration (TSA). CEVA also scans over dimension shipments with an Explosives Trace Detection (ETD) machine. CEVA’s scanning machine and process are audited regularly by the TSA.

Phase III

Phase III is split between Sam Slater’s CEVA Ground operation and a distribution center for a major retailer.

CEVA Ground operates one of the industry’s most comprehensive ground transportation and distribution networks in North America. CEVA Ground provides 1,500 scheduled linehaul segments supporting less than truckload (LTL) each week connecting all major gateways, ports and logistics centers, allowing access to additional capacity to accommodate surges in volume. The network serves the U.S. domestic market and closes the loop on international imports and exports through the on-forwarding of shipments coming into the U.S. gateways. CEVA Ground also offers full truckload (FTL) service to include dry van, reefer, flatbed and specialty equipment supported by a fleet of owner-operators and partner carriers.

The average length of haul is 630 miles including regionalized traffic. All of the power units used in linehaul have Qualcomm units. Most of the units are supplied by a cadre of regularly used owner-operators.

There are three regional planning groups in the Phase III network operation. They are supported by contractor liaison fleet managers and customer service. The fleet management/dispatch system used is TMW. Department of Transportation (DOT) compliance issues and other features used are color coded. Daily meetings are held at 9 A.M. between each of the managers and their sections.

A truckload brokerage operation was added last fall. This section is headed by Paul Warren. Truckload brokerage primarily handles transactional projects and specialty equipment. An industry-leading, externally hosted solution, Aljex, is used to manage third-party capacity.

Security Center

The Security Center operates 24/7/365. More than 80 CEVA locations in the U.S. are monitored using strategically placed TV cameras, and over 200 sites are monitored by DVR technology.

Energy – Oil & Gas

This is Bruce Hulings’ sector. CEVA has a large project logistics capability covering service providers, drillers, and oil companies.¹ CEVA has a SMART Solution for energy that lets it replicate Best Class practices quickly for new customers. CEVA’s energy solution hubs are Houston, Amsterdam, Dubai, Singapore, Aberdeen and Rio.

Hulings is justifiably proud of Houston’s Phase IV Energy Showcase. There are 160 employees involved in day-to-day management of supply chain logistics for Oil & Gas sector customers. The services housed in Phase IV are:

- Order Management (Supplier through Customer)

- Routing and ASN Management

- Warehousing

- Exception Alerts

- Shorebase Management (Africa, EMEA, North America)

- Reverse Logistics

- Control Tower TMS (With Phase III)

- Visibility and Support

There are 17 interconnected departments in Phase IV. There have been 107 Kaizen projects generated by employees. (The employee name and photo are shown on each process improvement report.) Kaizen events are shared with all CEVA locations.

Global standardized metrics are used throughout the office. Cubicles are standardized with black trim. Two areas, about 1′ x 1′, can be used on the facing wall for personal items. Flow boxes (rolling open filing cabinets) and heijunkas (shelving cases) have been designed by employees for maximum paperwork visibility and handling.

Matt Ryan, CEO – Americas, points out, “Everyone is empowered to drive change.” This dictum is especially true in Phase IV.

Most of the employees in Phase IV are managing orders globally from origin to destination. They work extensively with Phase III counterparts on the transportation requirements and contract logistics personnel to control project materials and supplies.

The Phase IV building is 112,000 square feet; 25,000 square feet is office space. About 800 shipments (2,000 pieces) are received and consolidated daily for outbound shipments. Operations are currently 12 hours a day and plans are to expand to 18 hours.

Ninety percent of the shipments made from the Phase IV warehouse are crates (»175 a day are built). A large yard is used to store cable rolls and other products which will be used on oil rigs. Shelves are used for driller and supplier inventory. Small John Deere trucks used for transporting on rigs and at shore stations occupy an area. There are five call locations and thirteen blinking flashes at key points in the warehouse. The call locations provide quick access for managers. The thirteen lights let everyone know that everything is fine in an area (green) or there is a problem (red).

The current purchase order management system, c2c, designed for oil and gas operations, will be replaced shortly by a customized Matrix warehouse management/order management system. Inventory is color taped by month to provide a quick reference on its age. Airfreight turns in 13 days – ocean freight in 22. Colored tape, other than the current month, is hard to find.

Most shipments are made on flatbeds to nearby ports.

Phase V operations are very similar to Phase IV. Phase V is a dedicated warehouse for a multinational energy company.

To summarize, CEVA’s Houston facilities provide an interesting local example of the company’s emphasis on global standard operating procedures and evidence that many small enhancements across an operation add up to competitive advantage.

¹CEVA’s primary competitor, Panalpina, is primarily connected to major oil companies.

Sources: A&A Primary Research, http://www.cevalogistics.com/