APL Logistics’ China operations have the following Certificates, Licenses, and Awards:

- ISO9001:2000 Certification for Import & Export and Logistics operations

- International and Domestic Freight Forwarding Licenses

- Customs Brokerage Licenses

- Import and Export License with “AA” Award

- Domestic Transport License

- 4A Logistics Certificate

As part of our visit, we had the opportunity to tour two warehousing operations previously run by the APLL-Zhiqin joint venture. They are detailed below.

APL Logistics’ Dedicated Huiyang Production Distribution Center Operation

APL Logistics manages a dedicated warehousing and distribution operation for a large multinational computer manufacturer in the Huiyang District of Huizhou, China. As an LLP (lead logistics provider) for its customer, APL Logistics manages all of its distribution center operations in China. Since 2003, APL Logistics has been supporting the customer’s Huiyang manufacturing plant operations by fulfilling orders and distributing products within China and internationally.

Product in four-high racking

Part of APLL’s fleet

The PDC has 5 outbound and 3 inbound doors

In 2006, APL Logistics moved into its current 124,000 square foot warehouse located approximately 500 meters away from the production facility. The operation functions as one of its customer’s Chinese production distribution centers (PDCs). It runs in a Lean/Six Sigma process

improvement environment and operates 24 hours/7 days a week.

Over 96% of computers produced and transferred from the manufacturing operation are received into the APL Logistics warehouse within hours of final production. The operation utilizes APL Logistics’ proprietary WMS (warehouse management system) which interfaces with its customer’s TMS (transportation management system).

The TMS consolidates purchase orders into shipments and directs warehouse picking and overall order management. Picking is performed within set work zones using pick lists. Approximately 80% of the warehouse picking is item/case pick and 20% is bulk or full pallet pick.

APL Logistics has a KPI (key performance indicator) to process orders within a six-hour window from order receipt to shipping. The majority of orders are built-to-order and require the customer’s computers to be merged with printers, monitors, and accessories manufactured by other OEMs (original equipment manufacturers). APL Logistics manages the inventory for these OEMs through multiple VMI (vendor managed inventory) programs. On-hand finished goods inventory is kept to a minimum.

As part of its transportation management operations, APL Logistics performs final deliveries using its fleet of 160 trucks as well as contracted motor carriers. APL Logistics utilizes its own fleet for last mile deliveries in Guangzhou, Wuhan, Changsha, Zhengzhou, Beijing and Shanghai.

APL Logistics has been awarded with an Excellent Service Provider award for its performance for the customer.

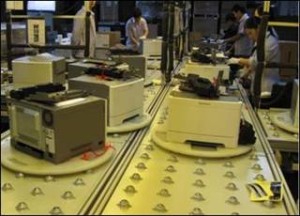

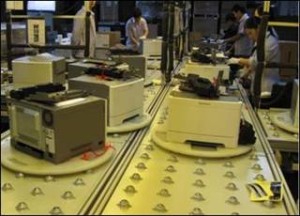

APDC / SMI / Asia Customization and Testing Center

Since 2009, APL Logistics has been running three distinct supply chain management functions for a high-tech customer from one facility in the Futian Free trade Zone (FTZ) section south of Shenzhen. The three-floor, 125,000 square foot operation serves the customer’s Asia Pacific

One building, three supply chain management functions

Two laser printer configuration lines

Distribution Center (APDC), its SMI (supplier managed inventory) hub, and Asia Customization and Testing Center. Having the three functions within one facility reduces the amount of product handling from configuration through testing and distribution.

For systems, the operation uses APL Logistics’ proprietary WMS interfaced to its customer’s SAP ERP (enterprise resource planning) system.

The APDC has a staff of 40 working in two shifts, six days per week. Seven people work in customs.

Approximately 3,200 SKUs (stock keeping units) of printers, cartridges, and accessories are maintained in inventory. APL Logistics has a two-hour order-to-ship cycle time and the operation processes approximately 30-50 export orders per day. Most orders require single or multiple item picks and are packed out.

As a value-added service, some kitting is performed to match printers with market appropriate power cables and accessories. In addition, some market specific product labeling is performed.

On the top floor of the operation, three laser printer configuration lines and one inkjet customization line are run by a staff of 20.

The final customization of printer models is performed by adding parts and components to the core printer “engine” as required for a specific printer model. Approximately 80 different printer models are customized over the course of a year. Parts and components from seven suppliers are held in a segregated and secure 40,000 square foot APL Logistics-managed SMI hub adjacent to the lines until they are required for assembly. The laser printer lines can configure approximately 10 printers per hour and the inkjet line can configure 80 printers per hour. A quality check is performed on each printer prior to final packaging.

In the last operation, different models of printers are tested. Each model can be tested for basic functionality, paper feeding, online function, condition, and ink cartridge testing. Approximately 500 printers are tested daily.

APL Logistics – China Operations Summary

Given the quality and level of value-added services performed at the two previous joint venture operations we visited, the acquisition of Zhiqin Group strategically solidifies APLL’s China value-added warehousing and distribution operations. In conjunction with APLL’s international transportation management services, its offering provides customers with an integrated service offering which can support international trade, or help customers grow business within the domestic China market.