enVista Leverages its Supply Chain Consulting Experience in Developing 3PL Transportation Management Operations

Indianapolis, Indiana USA Site Visit

June 21, 2010

By

Evan Armstrong

Key Personnel:

Jim Barnes, President and Sr. Managing Partner, enVista

Stephen Craig, Sr. Managing Partner, Freight Management (3PL, managed transportation)

Eric Schuss, Sr. Managing Partner, Enterprise Solutions (Microsoft Dynamics AX ERP)

Ken Mullen, Sr. Managing Partner, Supply Chain Services (supply chain consulting)

John Stitz, Sr. Managing Partner, Transportation Consulting (carrier sourcing and audit)

J.J. Schambow, Director of Marketing

enVista Overview

We are seeing an emerging trend of consulting/I.T. (information technology) companies offering 3PL services and enVista is one of the firms signifying this trend. Founded in 2002, enVista is a growing supply chain consulting firm which added transportation network management capabilities in late 2008. Its vision is to provide customers with a service offering that includes initial consulting and process improvement work, I.T. and process implementation, and then gives customers the opportunity to operate the redesigned supply chain operation. Executing on this vision, enVista has developed its 3PL operations and is now managing $50M in annualized freight spend and expects that number to increase to approximately $100M by 2011. enVista has a staff of 110 and its 2009 revenues were $12M. There are 12 people dedicated to its transportation management operation.

In addition to its 3PL transportation management services, enVista’s core consulting and implementation services include: supply chain network design, supply chain systems selection and implementation, labor management and productivity metric development, material flow analysis, facility layout and design, LEAN process improvements, supply chain training, Microsoft Dynamics AX ERP/CRM implementation and upgrades, carrier analysis and negotiation, and freight invoice audit/payment through its myShipINFO® Business Intelligence platform.

enVista’s freight audit and payment operation has approximately 400 customers and is processing over 130 million freight bill invoices annually representing over $925M in annual spend. Customers include: Brightpoint, Cummins, Epson, FredMeyer, GE, Hershey’s, Petco, See’s Candies, Sports Authority, and World Market.

3PL Inbound Transportation Management

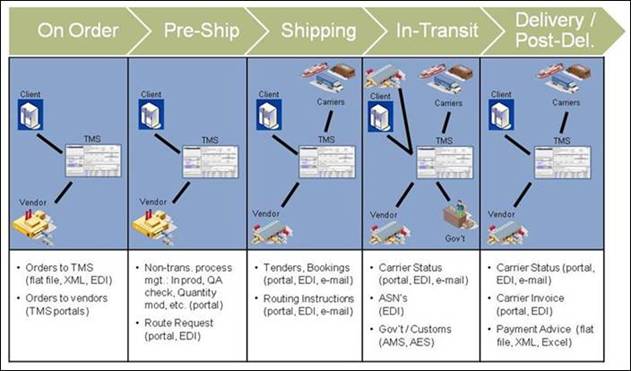

As a 3PL, enVista is managing around 12,000 inbound shipments a month from retail vendors to customer locations. It is providing some different PO (purchase order) flow management functionality including the ability of vendors to request ship date extensions and even request PO cancellations, all through vendor portals. enVista views developing tier-one inbound management processes as core to growing its transportation management business. enVista is currently using MercuryGate’s transportation management system (TMS) to link over 3,500 users from approximately 3,000 retail vendors for its inbound TM (transportation management) operations. The process overview is shown in the figure below.

enVista Inbound Retail TM Operational Process Flow

The inbound TM process details are as follows:

- On Order: Standard purchase orders from TM retail customers are sent to enVista’s TMS and to retail vendors for order fulfillment. Vendors in-turn specify when the order will be available for carrier pickup by providing the TMS with earliest available and latest possible pickup dates. These dates are used by enVista for transportation planning and optimization within MercuryGate. Hot orders that can be fulfilled by vendors move outside the standard process and are planned by enVista and booked with a carrier within six hours of being placed.

- Pre-Ship: enVista sends automated “route request” reminder e-mails to vendors with PO’s within a specified number of days prior to a “Do Not Ship Before” date. enVista continues to follow-up with vendors that have not made route requests, first with personal e-mails and eventually with phone calls. Vendors provide route requests directly in their vendor portal. These route requests become shipments which are planned/optimized using MercuryGate’s “Mojo” optimizer.

- Shipping: Once the mode is selected and routes are built, the resulting shipments are then reviewed by an enVista planner and electronically tendered to carriers. When the shipments are booked, vendors automatically receive routing instructions. For all truckload and intermodal loads, enVista Transportation Coordinators contact vendors directly. enVista is working with approximately 250 carrier contracts in its TM operations.

- In-Transit: enVista receives carrier electronic data interchange (EDI) 214 transit status messages that are automatically displayed to its customer and vendors through a Shipment Status Portlet. enVista is also incorporating receipt of EDI 856 advance shipping notice (ASN) messages from vendors into its TMS. enVista uses MercuryGate’s TMS to translate these inbound 856 ASN’s into outbound ASN’s which go to receiving facilities having different message specifications. The ASN’s are used by the receiving facilities to automate receiving and lower receiving costs. enVista is also able to improve inbound process reporting by comparing route requested quantities with the actual shipped amounts identified on the 856’s and generate Freight Term Optimization (FTO) reports.

- Post-Delivery: enVista provides planned shipment cost information to the customer’s existing third-party freight payment company for non-parcel auditing. It handles the parcel auditing for inbound and outbound parcel invoices through enVista’s myShipINFO® system. Upon receipt of audited carrier invoice data for parcel and non-parcel shipments, enVista updates shipment costs, allocates costs to the SKU (stocking keeping unit) level, and performs detailed GL (general ledger) account coding.

enVista Inbound Retail TM Process Consulting to Operational Results Stages

Enterprise Systems for Distribution Intensive Companies

In its Enterprise Systems (ES) consulting practice, enVista is a Microsoft Gold Certified partner focusing on implementing the Microsoft Dynamics AX ERP (enterprise resource planning) system. enVista has been a Microsoft partner for distribution-intensive businesses like: Two Men and A Truck, Flow Manufacturing, AER Technologies, Custom Chrome, and Hawaii Transfer. Prior to starting its own 3PL operation and Enterprise Systems group, enVista had worked with multiple 3PLs in selecting and implementing supply chain systems.

Hawaii Transfer Information Technology Consulting Case Study

Hawaii Transfer (HT) was founded in 1931 and is a $30M privately-held transportation and distribution logistics service provider. enVista was engaged by Hawaii Transfer in 2009 to develop an IT strategy that would support continued growth, reduce expenses, mainly related to manual data entry and labor, and enable delivery of additional and differentiated value-added services.

HT’s business challenges were typical for a rapidly growing/customer focused mid-sized value-added warehousing and distribution 3PL. Some examples include:

- Order entry and planning performed on multiple in-house tools and/or on customer supplied systems.

- Planning, executing and billing for services supported by a large number of desktop standalone solutions, including custom databases and complex Excel spreadsheets.

- Tracking of many billable activities was performed manually and prone to error or loss (non-entry).

- Multiple customer-specific billing systems were in use with some billing systems also performing program-specific accounts receivable (A/R) functions.

enVista is helping HT by deploying a technology strategy that leverages emerging SaaS (software as a service) systems to lower initial price points, convert some fixed costs to variable costs, and reduce the need to develop and maintain some current IT skill sets. SaaS tends to be a good fit for mid-sized 3PLs who need to deploy significant functionality quickly while minimizing costs.

enVista SaaS Integrated 3PL Systems Suite

enVista is using two components of it systems suite for Hawaii Transfer:

- Microsoft Dynamics AX is to be used initially for order management and financials and later it will be used for human resources, customer management, and other functions.

- Manhattan Associates SCALE warehouse management system (WMS) is being utilized for warehouse management, 3PL billing, labor management, and parcel processing.

A web portal for HT’s customers’ allows them to enter orders and provides them with visibility to on-hand inventory. The WMS can track storage and handling transactions for integrated 3PL billing. An integrated handheld POD (proof of delivery) solution also reduces data entry and further automates 3PL customer billing. All billing transactions flow through a single billing engine that manages contracts and applies costs to transactions based upon customer contracts. All warehouse and transportation transactions flow to a single financial system that provides business intelligence in real time.

Hawaii Transfer Supply Chain Systems Architecture

Summary

enVista is leveraging its supply chain expertise to meet the needs of 3PL transportation management and consulting customers. Its consulting to implementation to operations management service offering, is addressing customers’ needs. enVista’s success is in-turn fueling its growth and increasing profitability. We see this consulting/I.T./3PL business model growth as a continuing trend.